News

-

What is the role of the multilayer circuit board factory in the production of small household appliances?

Multilayer circuit board factory can be said to be a major contributor in the electronics industry, and it also plays an important role in the manufacture of small household appliances. With the continuous progress of science and technology, small household appliances are rapidly developing in a ...Read more -

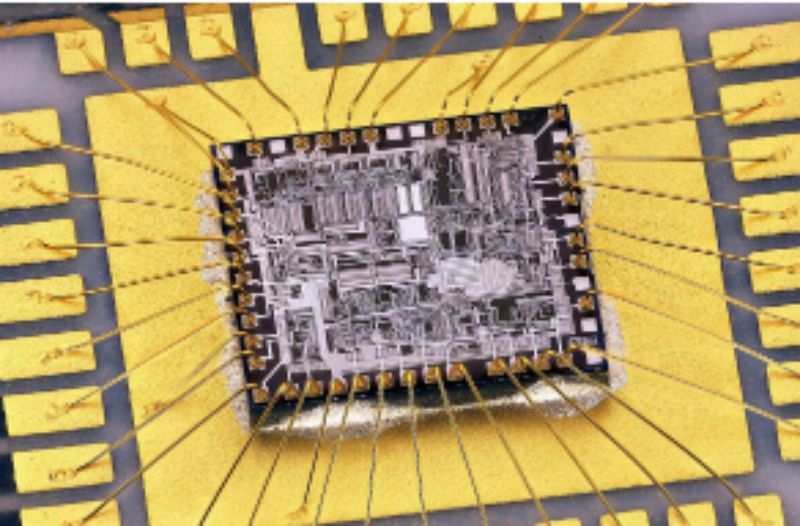

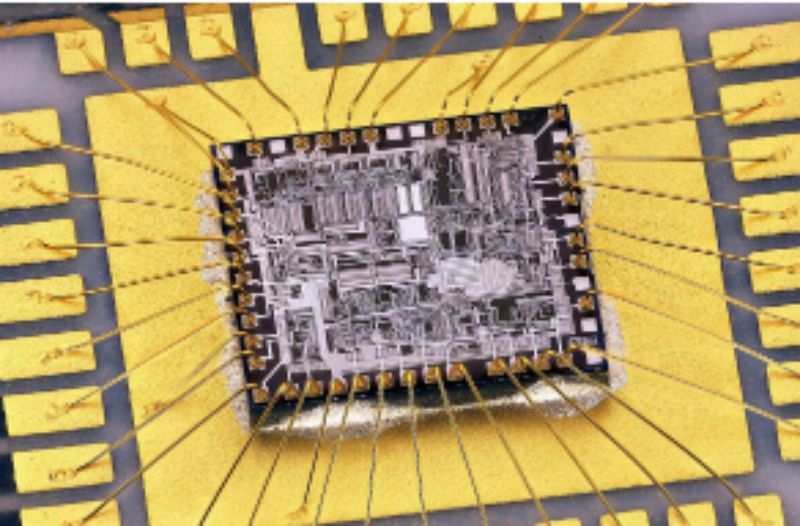

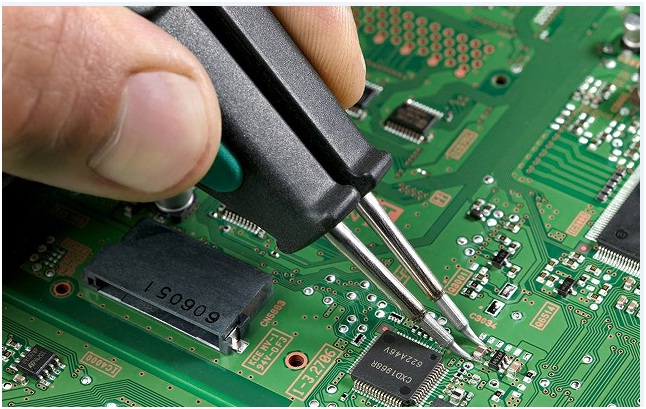

Wire Bonding

Wire bonding – the method of mounting a chip onto a PCB There are 500 to 1,200 chips connected to each wafer before the end of the process. In order to use these chips where needed, the wafer needs to be cut into individual chips and then connected to the outside and powered on. At this time, the...Read more -

Three PCB steel stencil processes

PCB steel stencil can be divided into the following types according to process: 1. Solder paste stencil: As the name suggests, it is used to apply solder paste. Carve holes in a piece of steel that correspond to the pads on the PCB board. Then use solder paste to pad print onto the PCB board thro...Read more -

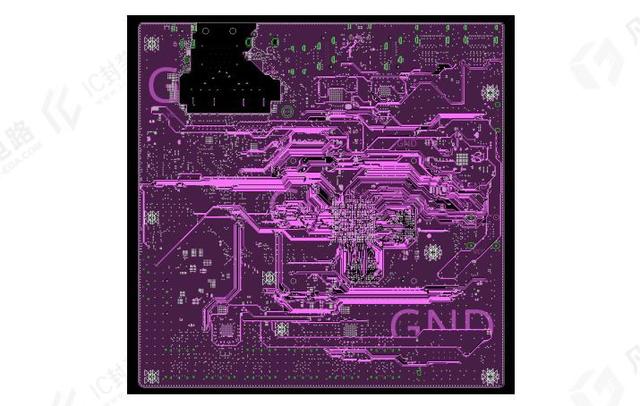

Why can’t PCB line go right Angle?

In PCB production, the design of the circuit board is a very time-consuming and does not allow for any sloppy process. In the PCB design process, there will be an unwritten rule, that is, to avoid the use of right-angle wiring, so why is there such a rule? This is not a whim of the designers, but...Read more -

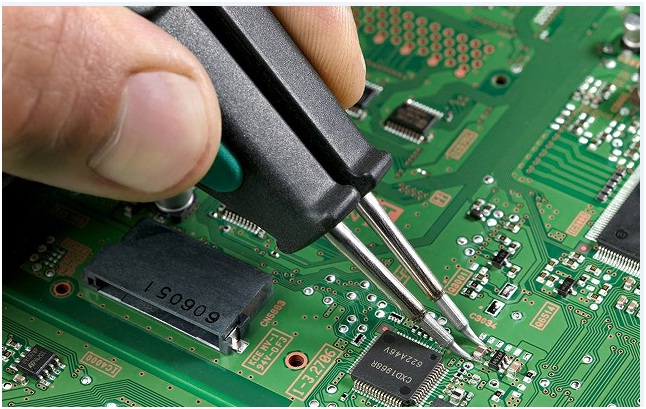

What causes black PCBA circuit board welding plate?

PCBA circuit board welding disc black problem is a more common circuit board bad phenomenon, resulting in PCBA welding disc black for many reasons, but usually caused by the following reasons: 1, pad oxidation: If the PCBA pad is exposed to humidity for a long time, it will cause the surface of t...Read more -

What is the impact of PCB surface treatment process on SMT welding quality?

In PCBA processing and production, there are many factors that affect the quality of SMT welding, such as PCB, electronic components, or solder paste, equipment and other problems at any place will affect the quality of SMT welding, then PCB surface treatment process will have what impact on the ...Read more -

What are the characteristics of PCB aluminum substrate?

Aluminum substrate as a special kind of PCB, its application field has long been all over the communication, power, power, LED lighting and other industries, especially high-power electronic equipment will almost use aluminum substrate, and aluminum substrate is so popular, are due to its followi...Read more -

What are the apertures of pcb through holes?

There are many types of PCB through hole apertures, and different apertures can be selected according to different application requirements and design requirements. The following will detail the aperture of several common PCB through holes and the difference between PCB through holes and through ...Read more -

What is FPC Printed Circuit Board?

There are many kinds of circuit boards on the market, and the professional terms are different, among which the fpc board is very widely used, but many people do not know much about the fpc board, so what does the fpc board mean? 1, fpc board is also called “flexible circuit board”, i...Read more -

The Importance of Copper Thickness in PCB Manufacturing

PCBs in sub-products are an integral part of modern electronic equipment. Copper thickness is a very important factor in the PCB manufacturing process. The correct copper thickness can ensure the quality and performance of the circuit board, and also affects the reliability and stability of elect...Read more -

Exploring the World of PCBA: An In-Depth Overview of the Printed Circuit Board Assembly Industry

In the dynamic realm of electronics, the Printed Circuit Board Assembly (PCBA) industry plays a pivotal role in powering and connecting the technologies that shape our modern world. This comprehensive exploration delves into the intricate landscape of PCBA, unraveling the processes, innovations, ...Read more -

Detailed analysis of SMT PCBA three anti-paint coating process

As the size of PCBA components is getting smaller and smaller, the density is getting higher and higher; The height between the devices and the devices (the pitch/ground clearance between the PCB and the PCB) is also getting smaller and smaller, and the influence of environmental factors on the P...Read more