News

-

Copper pouring process for automotive PCBA processing

In the production and processing of automotive PCBA, some circuit boards need to be coated with copper. Copper coating can effectively reduce the impact of SMT patch processing products on improving the anti-interference ability and reducing the loop area. Its positive e...Read more -

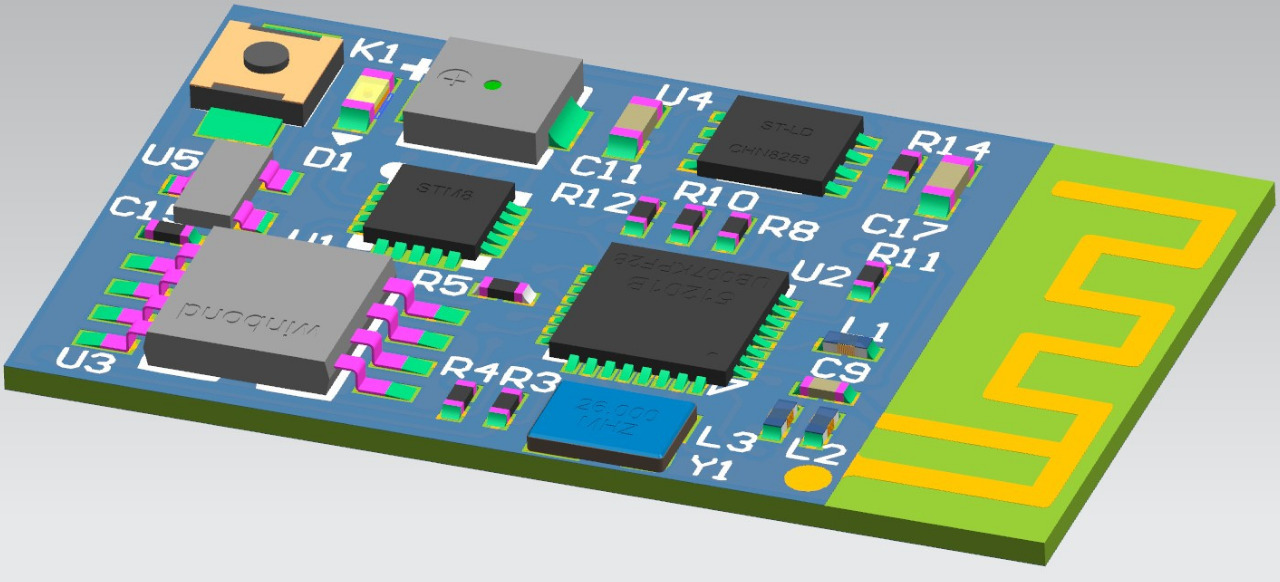

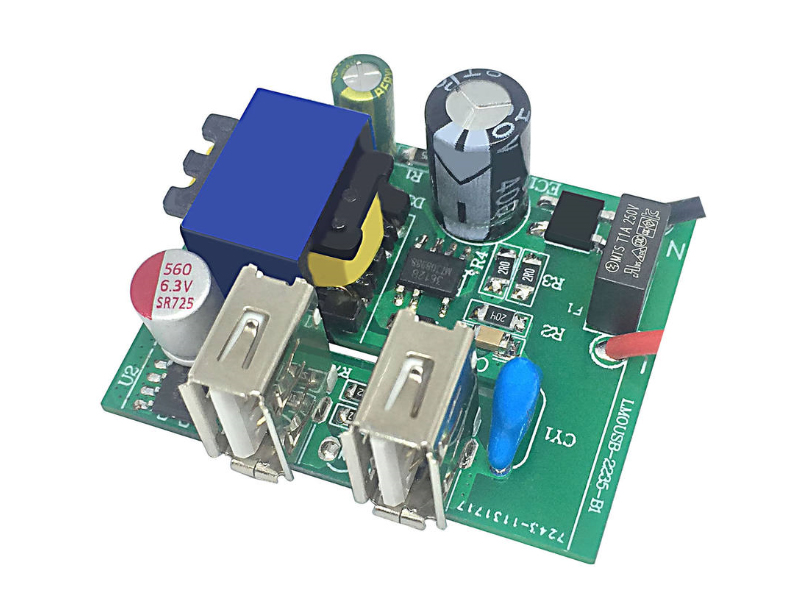

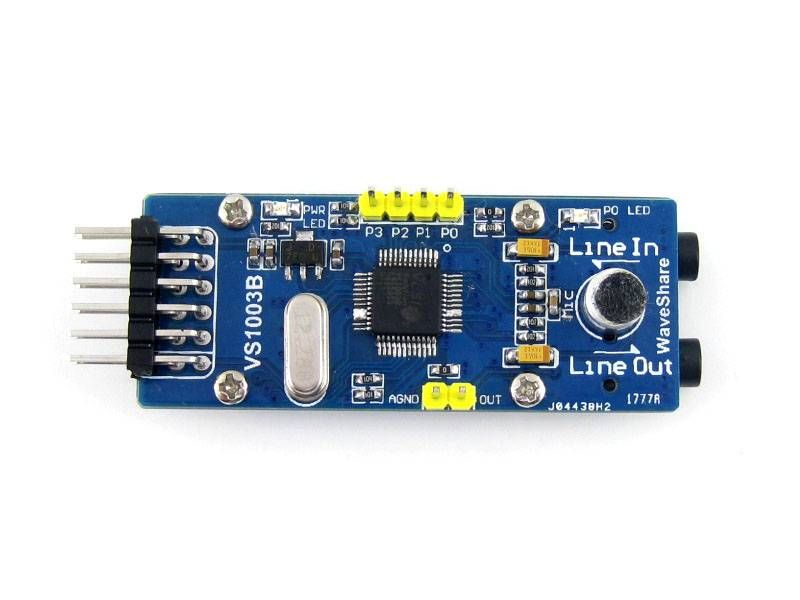

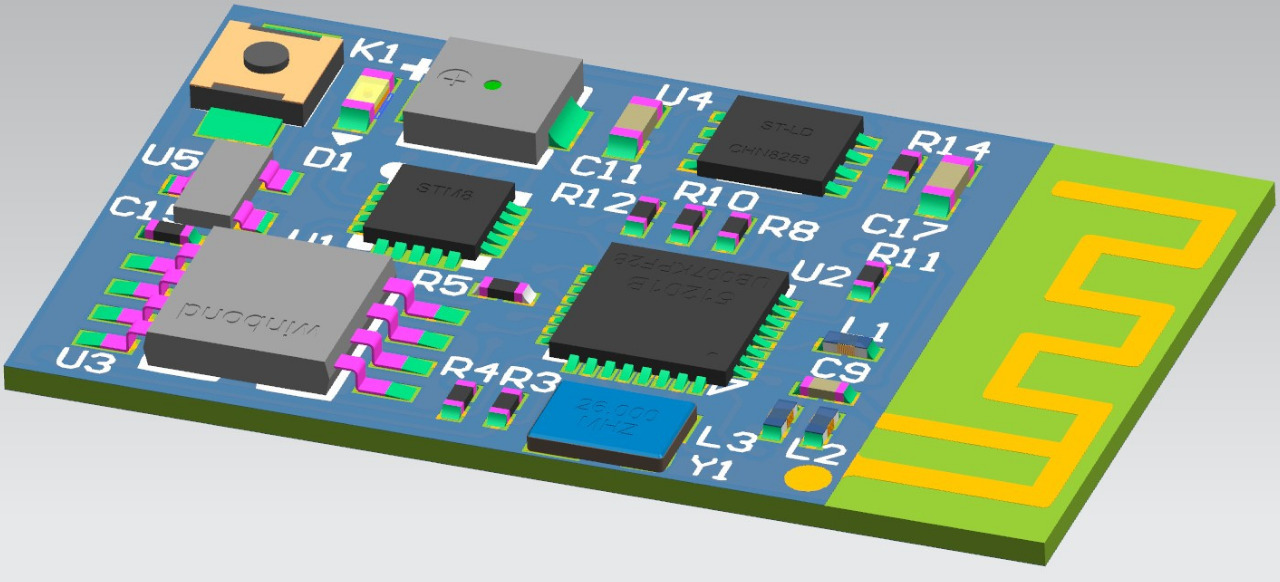

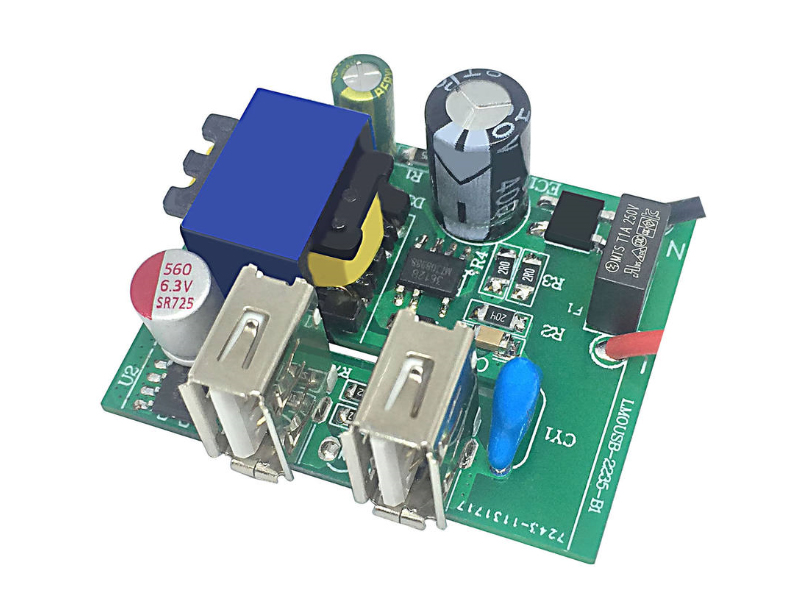

How to place both RF circuit and digital circuit on PCB board?

If the analog circuit (RF) and the digital circuit (microcontroller) work well individually, but once you put the two on the same circuit board and use the same power supply to work together, the entire system is likely to be unstable. This is mainly because the digital ...Read more -

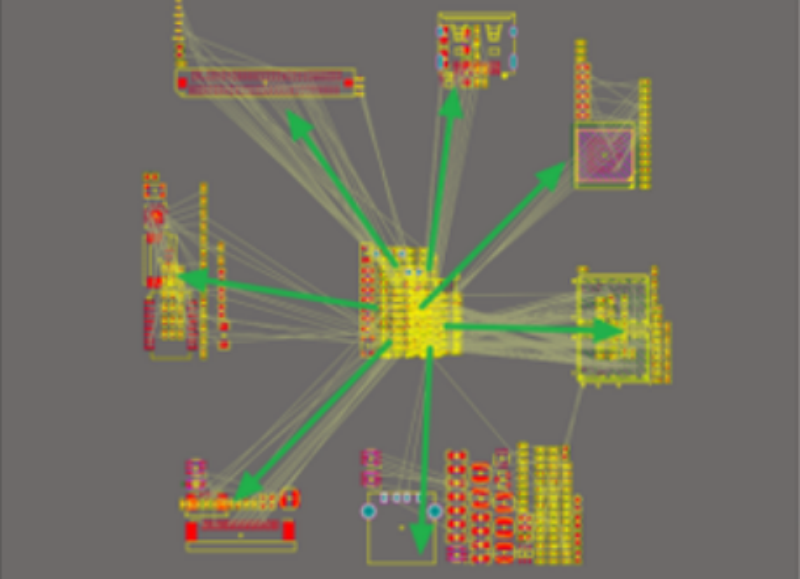

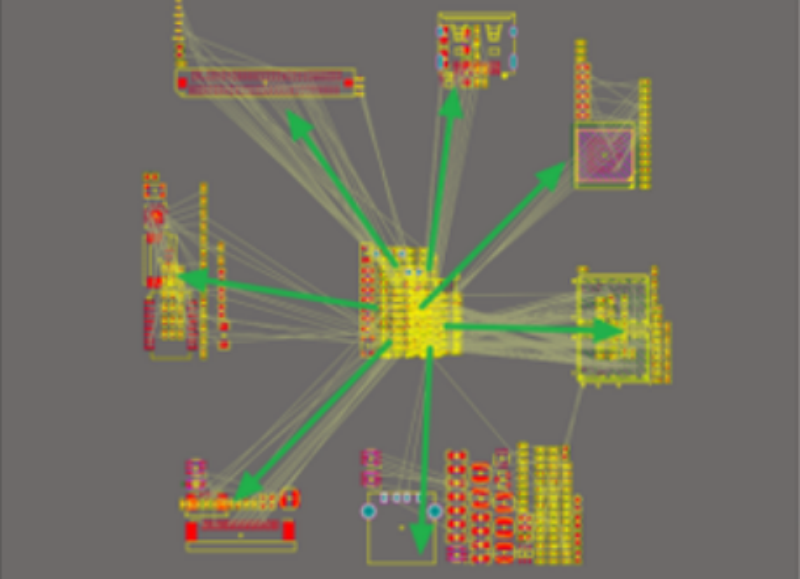

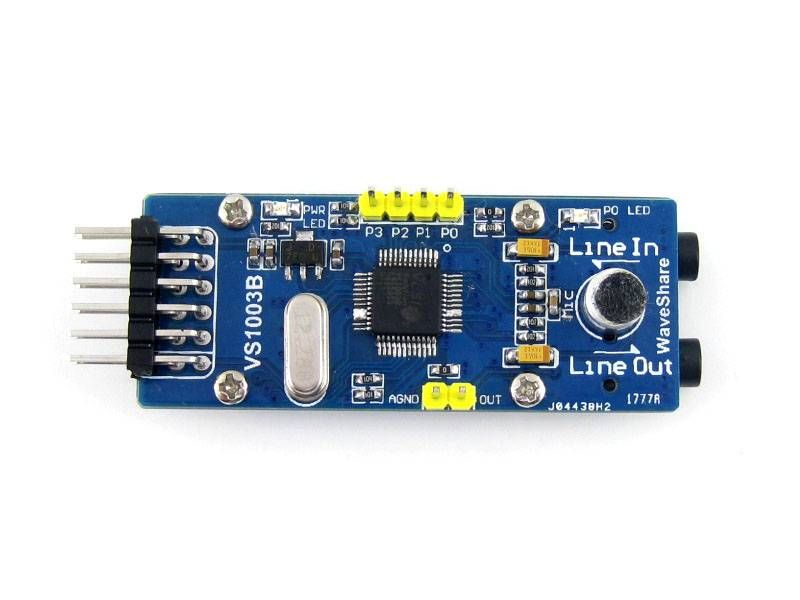

PCB general layout rules

In the layout design of the PCB, the layout of the components is crucial, which determines the neat and beautiful degree of the board and the length and quantity of the printed wire, and has a certain impact on the reliability of the whole machine. A good circuit board, ...Read more -

One, what is HDI?

HDI: high Density interconnection of the abbreviation, high-density interconnection, non-mechanical drilling, micro-blind hole ring in the 6 mil or less, inside and outside the interlayer wiring line width / line gap in the 4 mil or less, pad diameter of not more than 0....Read more -

Robust Growth Predicted for Global Standard Multilayers in PCB Market Expected to Reach $32.5 Billion by 2028

Standard Multilayers in the Global PCB Market: Trends, Opportunities and Competitive Analysis 2023-2028 The global market for Flexible Printed Circuit Boards estimated at US$12.1 Billion in the year 2020, is projected to reach a revised size of US$20.3 Billion by 2026, growing at a CAGR of 9.2%...Read more -

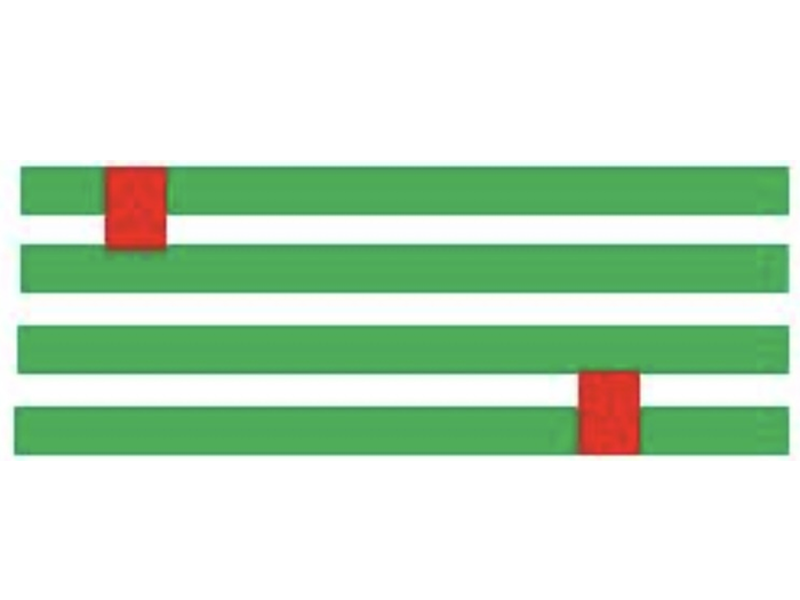

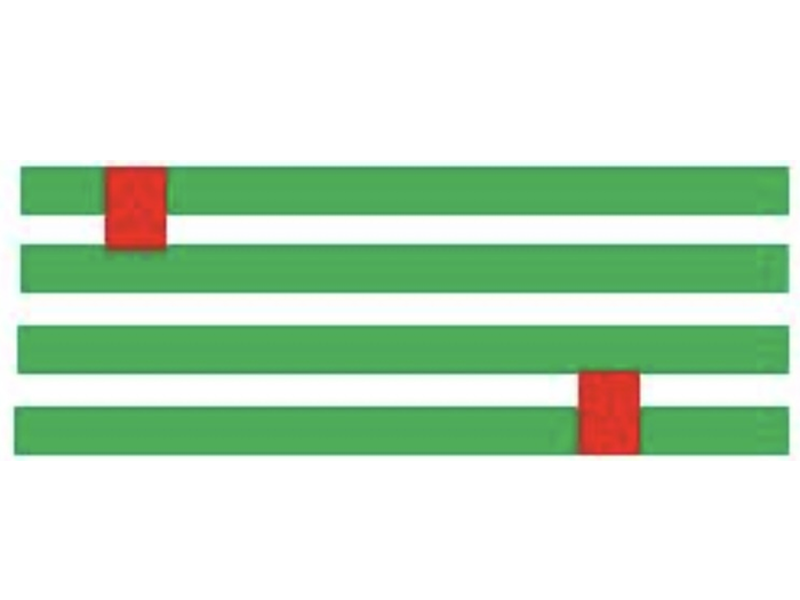

PCB slotting

1. The formation of slots during the PCB design process includes: Slotting caused by the division of power or ground planes; when there are many different power supplies or grounds on the PCB, it is generally impossible to allocate a complete plane for each power supply network and ground network...Read more -

How to prevent holes in plating and welding?

Preventing holes in plating and welding involves testing new manufacturing processes and analyzing the results. Plating and welding voids often have identifiable causes, such as the type of solder paste or drill bit used in the manufacturing process. PCB manufacturers can use a number of key stra...Read more -

Method of disassembling printed circuit board

1. Disassemble the components on the single-sided printed circuit board: toothbrush method, screen method, needle method, tin absorber, pneumatic suction gun and other methods can be used. Table 1 provides a detailed comparison of these methods. Most of the simple methods for disassembling electr...Read more -

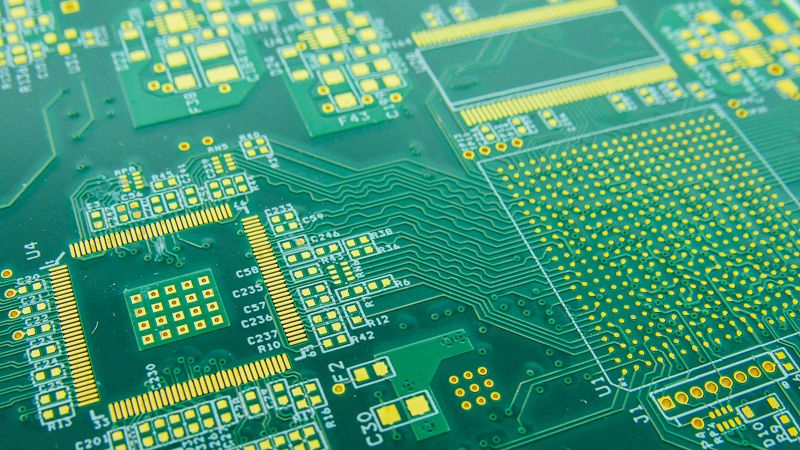

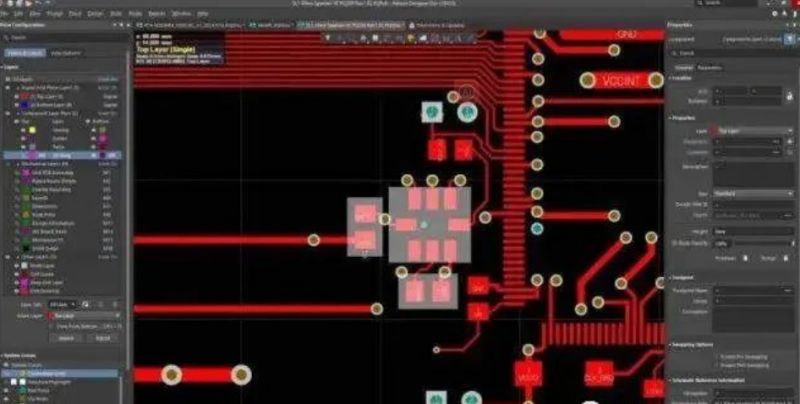

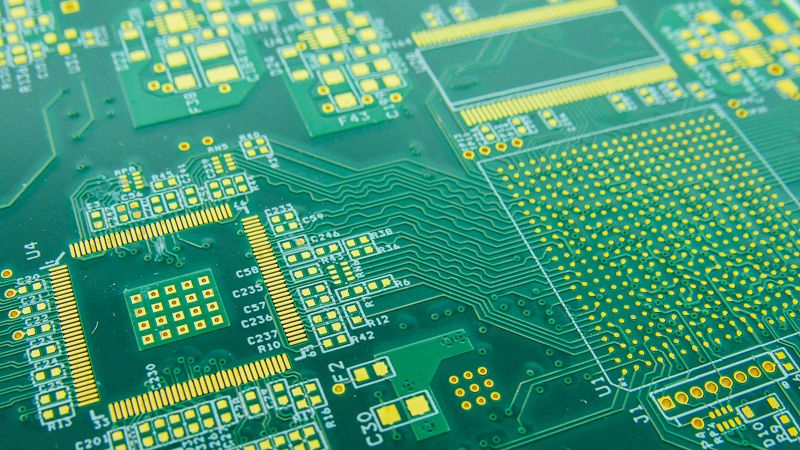

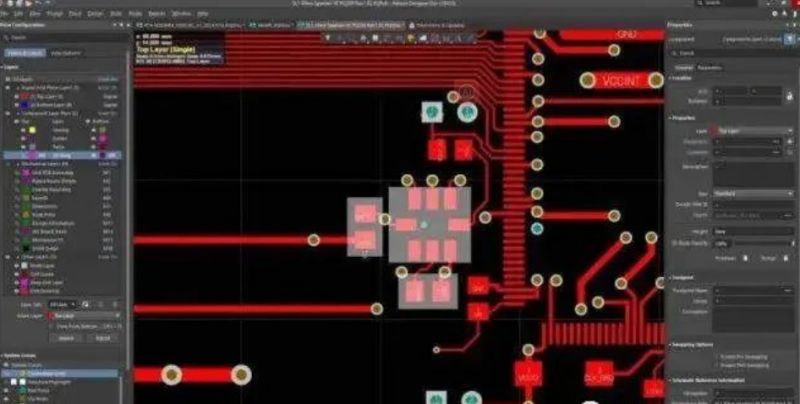

PCB design considerations

According to the developed circuit diagram, the simulation can be performed and the PCB can be designed by exporting the Gerber/drill file. Whatever the design, engineers need to understand exactly how the circuits (and electronic components) should be laid out and how they work. For electronics ...Read more -

Disadvantages of PCB traditional four-layer stacking

If the interlayer capacitance is not large enough, the electric field will be distributed over a relatively large area of the board, so that the interlayer impedance is reduced and the return current can flow back to the top layer. In this case, the field generated by this signal may interfere wi...Read more -

The conditions for PCB circuit board welding

1. The weldment has good weldability The so-called solderability refers to the performance of an alloy that can form a good combination of the metal material to be welded and the solder at an appropriate temperature. Not all metals have good weldability. In order to improve solderability, measur...Read more -

Welding of PCB board

The welding of PCB is a very important link in the production process of PCB, welding will not only affect the appearance of the circuit board but also affect the performance of the circuit board. The welding points of PCB circuit board are as follows: 1. When welding PCB board, first check the ...Read more