In the PCB production process, there is another important process, that is, tooling strip. The reservation of process edge is of great significance for the subsequent SMT patch processing.

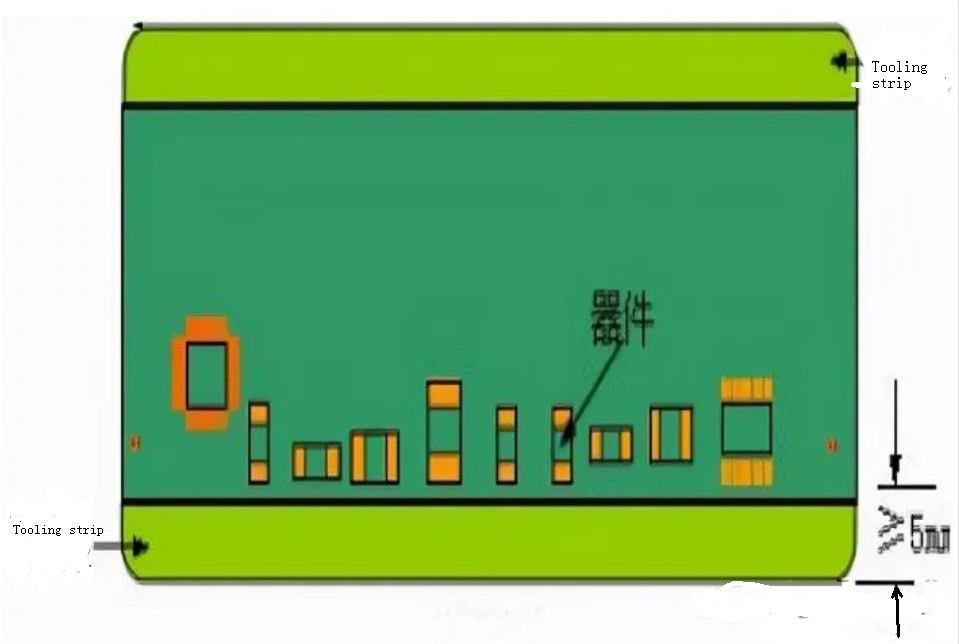

The tooling strip is the part added on both sides or four sides of the PCB board, mainly to assist the SMT plug-in to weld off the board, that is, to facilitate the SMT SMT machine track clamp the PCB board and flow through the SMT SMT machine. If the components too close to the track edge absorb the components in the SMT SMT machine nozzle and attach them to the PCB board, the collision phenomenon may occur. As a result, production cannot be completed, so a certain tooling strip must be reserved, with a general width of 2-5mm. This method is also suitable for some plug-in components, after wave soldering to prevent similar phenomena.

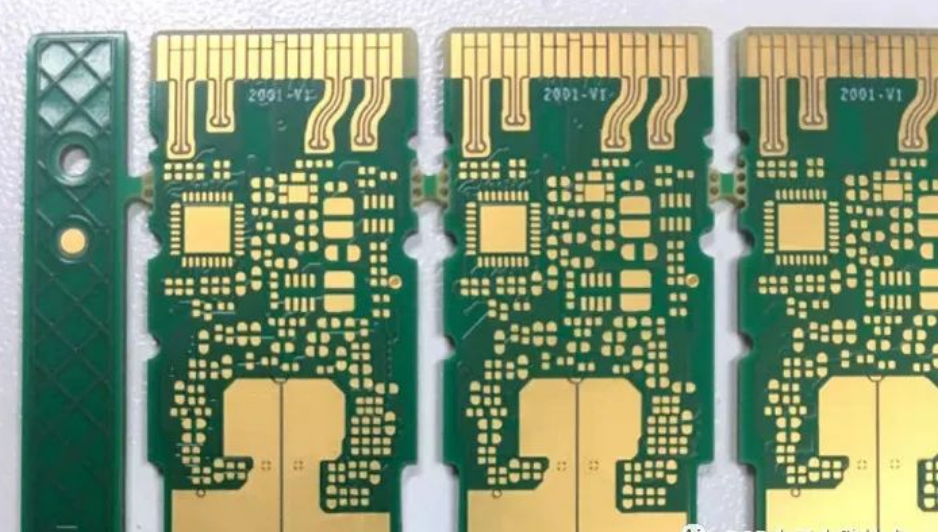

The tooling strip is not a part of the PCB board and can be removed after the PCBA manufacturing is completed

The way of produce the tooling strip:

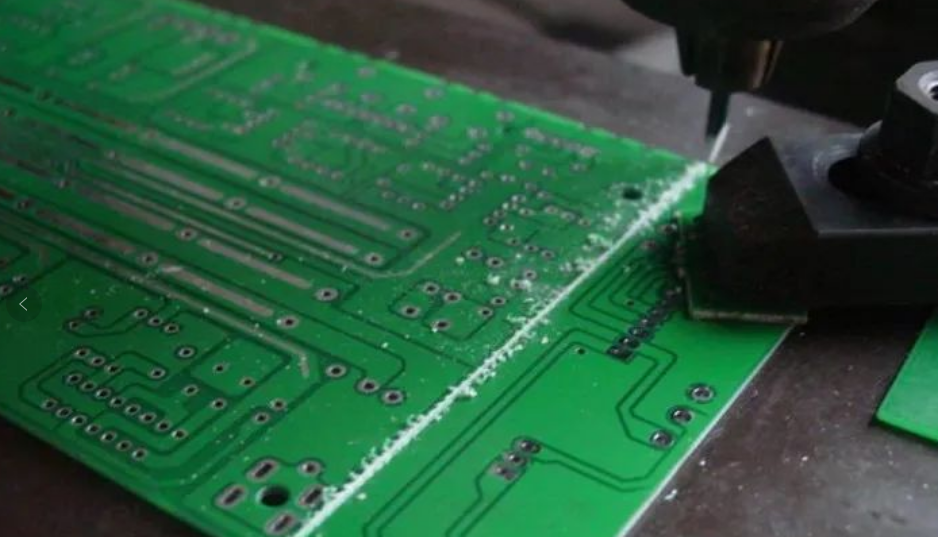

1, V-CUT: a process connection between the tooling strip and the board, slightly cut on both sides of the PCB board, but not cut!

2, Connecting bars: use several bars to connect the PCB board, make some stamp holes in the middle, so that the hand can be broken or washed off with the machine.

Not all PCB boards need to add tooling strip, if the PCB board space is large, leave no patch components within 5mm on both sides of the PCB, in this case, there is no need to add tooling strip, there is also a case of pcb board within 5mm on one side of no patch components, as long as add tooling strip on the other side. These need the attention of PCB engineer.

The board consumed by tooling strip will increase the overall cost of PCB, so it is necessary to balance economy and manufacturability when designing PCB process edge.

For some special shape PCB board, the PCB board with 2 or 4 tooling strip can be greatly simplified by cleverly assembling the board.

In the SMT processing, the design of the piecing mode needs to take full account of the track width of the SMT piecing machine. For the piecing board with a width exceeding 350mm, it is necessary to communicate with the SMT supplier’s process engineer.