Nekuenderera mberi kwekufambira mberi kwekuvaka kwe5G, minda yeindasitiri yakadai seyakanyatsojeka microelectronics uye ndege uye Marine yakagadziridzwa zvakare, uye minda iyi yose inovhara kushandiswa kwePCB circuit board. Panguva imwecheteyo yekuenderera mberi kwekusimudzira kweiyi indasitiri yemagetsi, tichaona kuti kugadzirwa kwezvinhu zvemagetsi kunoitwa zvishoma nezvishoma, kutetepa uye kujeka, uye zvinodikanwa zvemazvo zviri kuramba zvichikwira nekukwira, uye laser welding seyo inonyanya kushandiswa kugadzira tekinoroji muindasitiri yemicroelectronics, inosungirwa kuisa yakakwirira nepamusoro zvinodiwa pane welding degree yePCB circuit board.

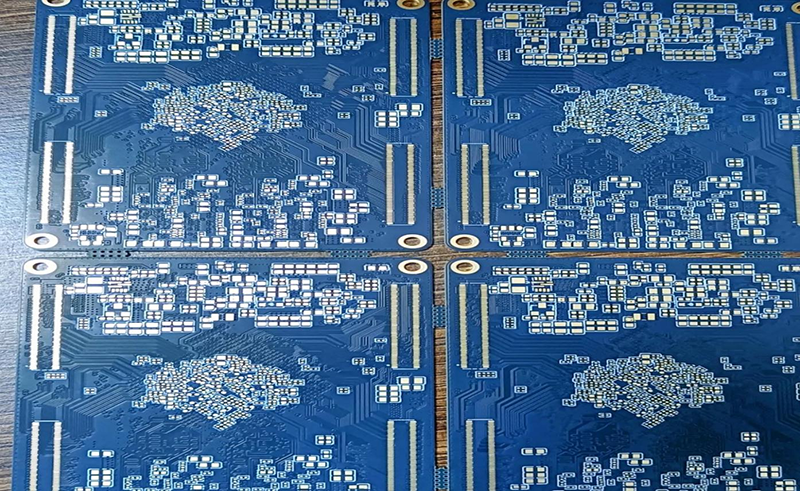

Kuongorora mushure mekuputika kwePCB redunhu bhodhi kwakakosha kumabhizinesi nevatengi, kunyanya mabhizinesi mazhinji akasimba muzvigadzirwa zvemagetsi, kana ukasazvitarisa, zviri nyore kuve nekutadza kwekuita, kukanganisa kutengesa kwechigadzirwa, asi zvakare kukanganisa chimiro chekambani uye mukurumbira. Iyo laser welding michina inogadzirwa neShenzhen Fastline Circuits ine kukurumidza kushanda, yakakwira welding goho, uye post-welding yekuona basa, iyo inogona kusangana nezvinodiwa zvewelding processing uye post-welding yekuona kwemabhizinesi. Saka, sei kuona kunaka PCB redunhu bhodhi pashure welding? Aya anotevera Fastline Circuits anogovera akati wandei anowanzo shandiswa nzira dzekuona

01 PCB triangulation nzira

Chii chinonzi triangulation? Kureva, nzira inoshandiswa kutarisa matatu-dimensional chimiro. Parizvino, nzira ye triangulation yakagadziridzwa uye yakagadzirirwa kuona chimiro chechikamu chemuchinjikwa chemidziyo, asi nokuti nzira ye triangulation inobva kune chiitiko chechiedza chakasiyana nenzira dzakasiyana, migumisiro yekucherechedza ichave yakasiyana. Muchidimbu, chinhu chacho chinoedzwa kuburikidza nemusimboti wekupararira kwechiedza, uye nzira iyi ndiyo yakakodzera uye inoshanda zvikuru. Kana iri welding surface pedyo negirazi mamiriro, nzira iyi haina kukodzera, zvakaoma kuzadzisa zvinodiwa zvekugadzira.

02 Chiedza chekuratidzira kugovera kuyerwa nzira

Iyi nzira inonyanya kushandisa chikamu chewelding kuona kushongedza, mwenje wechiitiko chemukati kubva kune yakarerekera nzira, kamera yeTV inoiswa pamusoro, uye ipapo kuongorora kunoitwa. Chikamu chinonyanya kukosha cheiyi nzira yekushanda ndechokuti ungaziva sei nzvimbo yeAngle yePCB solder, kunyanya kuziva ruzivo rwekuvhenekera, nezvimwewo, zvakakosha kutora ruzivo rweAngle kuburikidza nemhando dzakasiyana-siyana dzechiedza. Pane zvinopesana, kana yakavhenekerwa kubva kumusoro, iyo Angle yakayerwa ndiyo inoratidzwa chiedza kugovera, uye yakarereka pamusoro peiyo solder inogona kutariswa.

03 Shandura Angle yekuongorora kamera

Nzira yekuona PCB mushure mekugadzirisa? Uchishandisa nzira iyi kuona kunaka kwePCB welding, zvinodikanwa kuve nemudziyo une Angle inochinja. Chishandiso ichi chinowanzo kuve nemakamera mashanu, akawanda emagetsi emwenje e LED, achashandisa mifananidzo yakawanda, achishandisa mamiriro ekuona pakuongorora, uye kuvimbika kwakanyanya.

04 Focus yekuona kushandiswa nzira

Kune mamwe mabhodhi ematunhu akakwirira-density, mushure mePCB welding, nzira nhatu dziri pamusoro dzakaoma kuona chigumisiro chekupedzisira, saka nzira yechina inoda kushandiswa, kureva, kutarisa kushandiswa kwekushandisa nzira. Iyi nzira yakakamurwa kuva yakawanda, yakadai seye-multi-segment focus method, iyo inogona kuona zvakananga kureba kwechiso chekutengesa, kuti iwane nzira yekuongorora yepamusoro-soro, paunenge uchiisa 10 kutarisa pamusoro pekuona, unogona kuwana nzvimbo yekutarisa nekuwedzera kuburitsa, kuti uone nzvimbo ye solder. Kana ikaonekwa nenzira yekupenya micro laser danda pachinhu, sekureba gumi chaiwo pinholes akadzedzereka munzira yeZ, iyo 0.3mm pitch lead mudziyo inogona kunyatsoonekwa.