Comparison between manual design and automatic design in printed circuit board design

The extent to which automated methods are used to develop printed circuit board designs and generate wiring diagrams depends on many factors. Each method has its most suitable range of use to choose from.

1. Manually design and generate wiring diagrams

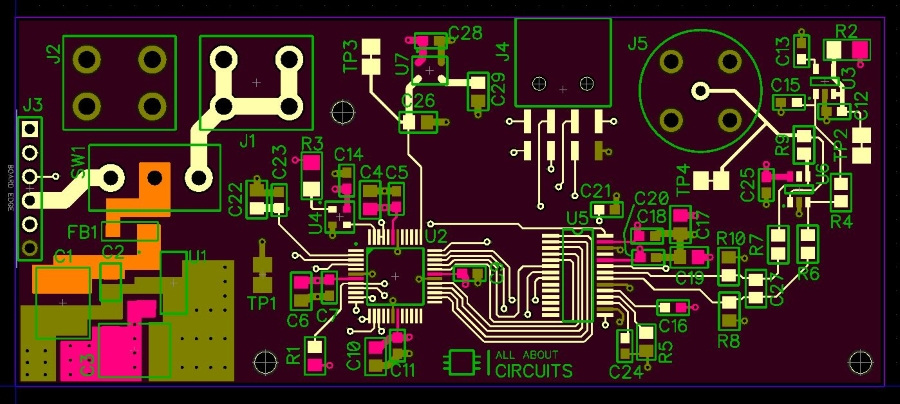

For simple single- and double-sided panels, manual design is the preferred method, and it can also be successfully used for the production of single products or small batches of circuits with higher complexity. Hand-designed with high mobility and all possible human ingenuity. However, for high-complexity digital circuit boards, especially those containing more than 100 integrated circuits, it is difficult to design them manually. Manual methods are also limited in terms of quality, time and the number of trained personnel required. Worldwide, a large percentage of printed circuit board design and wiring diagram generation is still done manually. The completely manual method does not require any investment, so it is more often used, although the parts it can achieve have become less and less, especially in the design of digital printed circuit boards.

2. Automatic design

Fully automated printed circuit board design and layout generation is highly valuable and requires standardized input with a small number of simple implementation specifications. It is an ideal tool for designing high-precision, complex digital circuit boards containing more than 150 integrated circuits, as well as challenging multi-substrate designs. Total design time can be reduced from weeks to days, and an almost perfect result can be achieved. For the design of large quantities of printed circuit boards, it is important to have a strict schedule and require minimal debugging and correction, making CAD often the preferred method. Automatic drawing of wiring diagrams also provides greater accuracy than hand drawing or tape-on methods. Analog printed circuit boards usually do not use automated design because, unlike digital circuits, it is difficult to simplify various design conditions for most analog printed circuit boards and to generate an intuitive and simple implementation specification table.

Significant investments in CAD equipment always require that the system be fully utilized. If the board contains less than 20 integrated circuits, more than 50% discrete components, or only a small number of printed circuit boards are required, using CAD is almost ineffective.