It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Original Factory 8 Layer Microvia HDI PCB, UHD, Display Controller Board, High Tg Motherboard, RF PCB, Rigid Printed Circuit Board, We welcome you to definitely be a part of us during this path of making a affluent and productive business enterprise together.

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for China PCB and Microvia HDI PCB, Our faith is to be honest first, so we just supply high quality merchandise to our customers. Truly hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our goods !

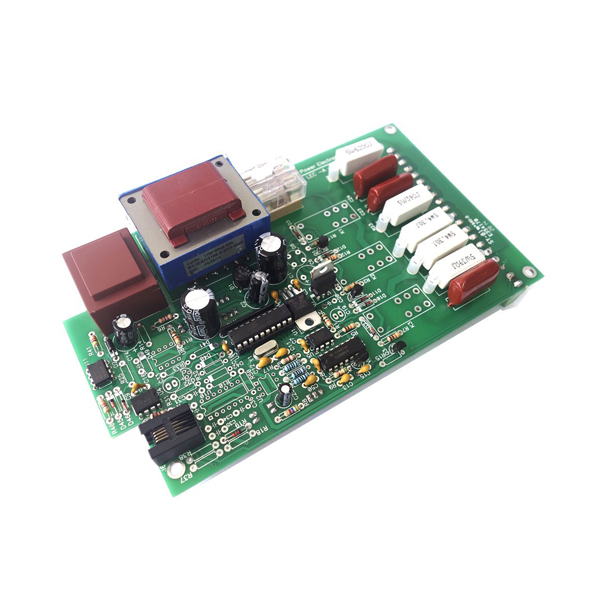

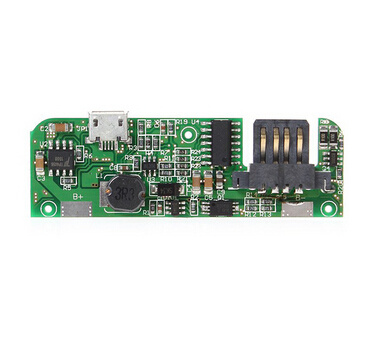

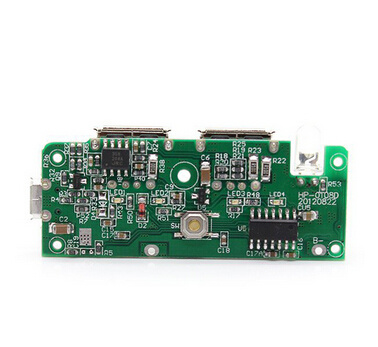

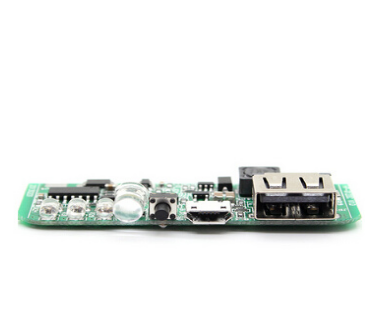

Power Bank PCBA for Controller Board/PCB Circuit Board Assembly Manufacturer

1.Introduction of Power Bank PCBA for Controller Board

PCBA Technology:

1)Professional Surface-mounting and Through-hole soldering Technology.

2)Various sizes like 1206,0805,0603,0201, 1005 components SMT technology.

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL, CE, FCC, RoHs Approval.

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line.

7) High density interconnected board placement technology capacity.

PCBA Manufacturing Capability:

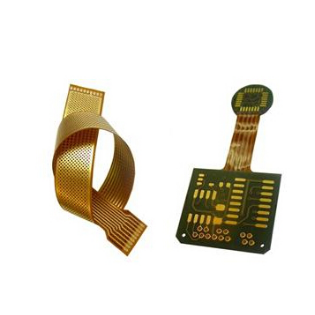

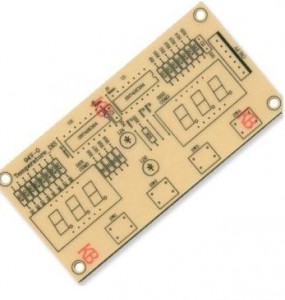

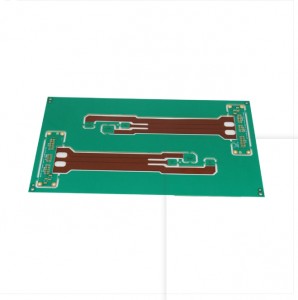

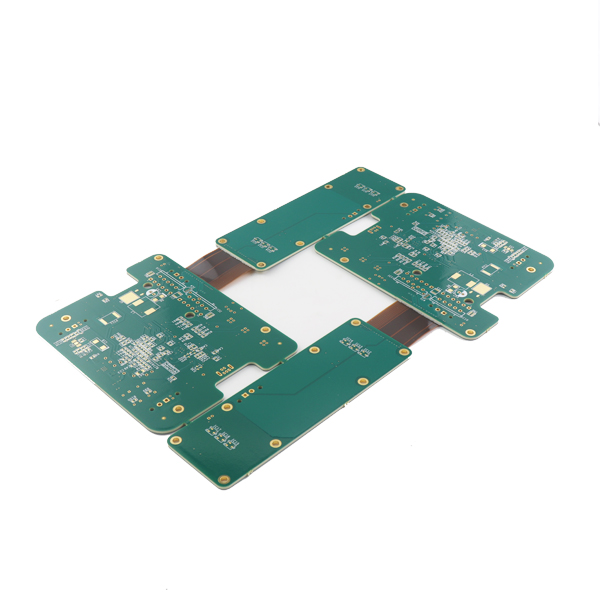

Fastline Circuits Co.,Limited has the most diversified printed circuit board technologies available, including Single-sided PCB, Multilayer PCB, Aluminum based PCB, HDI PCB, Rigid-flex PCB, Flexible PCB, Heavy Copper PCB, Ceramic PCB, Sure there still is mostly PCB assembly.

Types of Assembly: THD (Thru-Hole Device) ; SMT (Surface-Mount Technology) ; SMT & THD mixed ; 2 sided SMT and THD assembly

SMT Line Quantity: 30

SMT Line Quantity: 01005

SMT Min Pitch-QFP: 0.3mm

BGA-Min Pitch: 0.25mm

Component Package: Reels ; Cut tape; Tube and tray ;Loose parts and bulk

Board dimensions: Smallest size: 50*50mm ; Largest size: 520*420mm

Board shape: Rectangular ; Round ;Slots and Cut outs ;Complex and Irregular

Board type: Rigid FR-4 ; Rigid-Flex boards ; Aluminum PCB

Assembly process: Lead-Free (RoHS)

Design file format: Gerber RS-274X ; BOM (Bill of Materials) (.xls, .csv, . xlsx)

Testing Procedures : Visual inspection ; X-ray Inspection ;AOI (Automated Optical Inspection) ; ICT (In-Circuit Test) ; Functional testing

Turnaround time: 1-5 workdays for only PCB assembly ; 10-16 workdays for full turn-key PCB assembly.

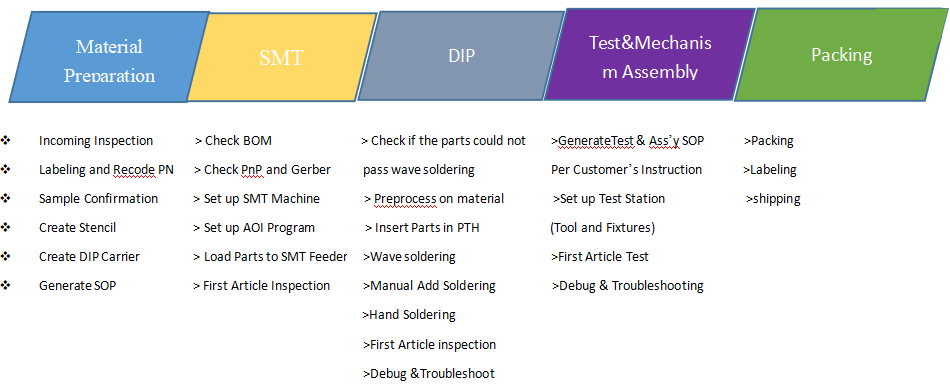

PCBA Flow:

We believe that the quality is the soul of an enterprise and provides time-critical, technologically advanced engineering and manufacturing services for the electronics industry.

Sound quality gains a good reputation for Fastline. Loyal customers has cooperated with us again and again and new customers come to Fastline to establish cooperation relationship when they hear of the great reputation. We look forward to offering high-quality service to you!

2.Production Details of Power Bank PCBA for Controller Board/PCB Circuit Board Assembly

3.Application of Power Bank PCBA for Controller Board/PCB Circuit Board Assembly

We have served high quality PCBA to numerous countries, from consumer electronics to telecommunications, new energy, aerospace, automotive, etc.

Electronic Product

Communications Industry

Aerospace

Industrial control

Car Manufacturer

Military Industry

4. Qualification of Power Bank PCBA for Controller Board/PCB Circuit Board Assembly

We have set a separated department where exclusive production planner will follow your order production after your payment, to meet your pcb production and assembly requirement.

We have below qualification to prove our pcba.

5.Customer visit

6.Our Package

We use vacuum and carton to wrap the goods, to ensure all them can reach to you completely.

7.Deliver And Serving

You can choose any express company that you have with your account, or our account, for heavier package, seaway shipping will be available, too.

When you get the pcba, don’t forget to check and test them,

If any problem, welcome to contact us!

8.FAQ

Q1: Are you a factory or trade company?

A1: We have our own PCB manufacturing & Assembly factory.

Q2: What’s your minimum order quantity?

A2: Our MOQ is not the same based on different items. Small orders are also welcome.

Q3: what file we should offer?

A3: PCB:Gerber file is better, ( Protel, power pcb, PADs file), PCBA : Gerber file and BOM list.

Q4: No PCB file/GBR file, only have the PCB sample, can you produce it for me?

A4: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5: What any other information should be offered except for file?

A5:Following specifications are needed for quotation:

a) Base material

b) Board thickness:

c) Copper thickness

d) Surface treatment:

e) color of solder mask and silkscreen

f) Quantity

Q6:I am very satisfied after I read your information, how can I start to purchase my order?

A6: Please contact our sales at homepage online, thank you!

Q7: What is delivery terms and time?

A7: We usually use FOB terms and ship the goods in 7-15 workdays depending on your order quantity, customization.