Isikrini sesilika sePCBushicilelo yinkqubo ebalulekileyo ekuvelisweni kweebhodi zesekethe PCB, emisela umgangatho webhodi PCB ogqityiweyo.Uyilo lwebhodi yesekethe PCB lunzima kakhulu.Kukho iinkcukacha ezininzi ezincinci kwinkqubo yoyilo.Ukuba ayiphathwanga ngokufanelekileyo, iya kuchaphazela ukusebenza kwayo yonke ibhodi yePCB.Ukuze ukwandise ukusebenza kakuhle koyilo kunye nomgangatho wemveliso, yeyiphi imiba ekufuneka siyiqwalasele ngexesha loyilo?

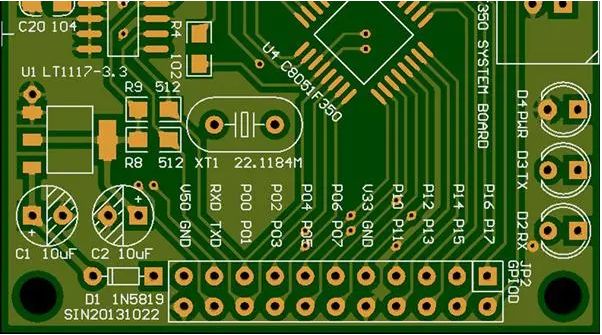

Imizobo yomlinganiswa zenziwe kwibhodi pcb ngesilika screen okanye inkjet yoshicilelo.Umlinganiswa ngamnye umele icandelo elahlukileyo kwaye udlala indima ebaluleke kakhulu kuyilo lwamva.

Mandazise abalinganiswa abaqhelekileyo.Ngokubanzi, C imele icapacitor, R imele isichasi, L imele inductor, Q imele transistor, D imele diode, Y imele crystal oscillator, U imele isiphaluka esidibeneyo, B imele ibuzzer, T imele isiguquli, K. imele iiRelays nokunye.

Kwibhodi yesekethe, sihlala sibona amanani afana ne-R101, C203, njl njl. Enyanisweni, unobumba wokuqala umele icandelo lecandelo, inani lesibini lichaza inombolo yomsebenzi wesekethe, kwaye inombolo yesithathu neyesine imele inombolo yesiriyali kwisekethe. ibhodi.Ngoko siyaqonda kakuhle ukuba i-R101 yi-resistor yokuqala kwisekethe yokuqala esebenzayo, kwaye i-C203 yi-capacitor yesithathu kwisekethe yesibini esebenzayo, ukwenzela ukuba ukuchongwa komlinganiswa kube lula ukuyiqonda.

Ngapha koko, abalinganiswa abakwibhodi yesekethe yePCB yinto esihlala siyibiza ngokuba sisikrini sesilika.Into yokuqala abathengi abayibonayo xa befumana ibhodi ye-PCB yisikrini sesilika kuyo.Ngokusebenzisa abalinganiswa besikrini sesilika, banokuqonda ngokucacileyo ukuba zeziphi izinto ezimele zibekwe kwindawo nganye ngexesha lofakelo.Kulula ukudibanisa isiqwenga kunye nokulungiswa.Ke zeziphi iingxaki ekufuneka ziqwalaselwe kwinkqubo yoyilo lokuprintwa kwesikrini sesilika?

I-1) Umgama phakathi kwesikrini sesilika kunye ne-pad: isikrini sesilika asikwazi ukufakwa kwi-pad.Ukuba i-pad igqunywe yi-silk screen, iya kuchaphazela i-soldering of components, ngoko ke kufuneka kugcinwe isithuba se-6-8mil. ebhekisa kububanzi be-inki.Ukuba ububanzi bomgca buncinci kakhulu, i-inki ayiyi kuphuma kwisikrini sokuprinta kwesikrini, kwaye iimpawu azikwazi ukuprintwa.3) Ubude bomlinganiswa wokuprintwa kwesikrini sesilika: Ubude bomlinganiswa bungaphezulu kwe-0.6mm (25mil).Ukuba ubude bonobumba bungaphantsi kwe-25mil, amagama ashicilelweyo awanakucaca kwaye abe luzizi lula.Ukuba umgca woonobumba ungqindilili kakhulu okanye umgama usondele kakhulu, kuya kubangela ukufiphala.

4) Isalathiso sokuprintwa kwesikrini sesilika: landela umgaqo ukusuka ekhohlo ukuya ekunene kwaye ukusuka ezantsi ukuya phezulu.

5) Inkcazo ye-polarity: Amacandelo ngokubanzi ane-polarity.Uyilo loshicilelo lwesikrini kufuneka lunikele ingqalelo ekuphawuleni izibonda ezilungileyo nezingalunganga kunye namacandelo alawulayo.Ukuba izibonda ezintle kunye nezibi ziguqulwa, kulula ukubangela isiphaluka esifutshane, okwenza ukuba ibhodi yesiphaluka itshise kwaye ayikwazi ukugqunywa.

6) Ukuchongwa kwephini: Ukuchongwa kwephini kunokwahlula ulwalathiso lwamacandelo.Ukuba iimpawu zesikrini zesilika ziphawula ukuchongwa ngokungalunganga okanye akukho kuchongwa, kulula ukubangela ukuba amacandelo afakwe umva.

7) Isikhundla sesikrini sesilika: Musa ukubeka uyilo lwesikrini sesilika kumngxuma owenziweyo, kungenjalo ibhodi ye-pcb eprintiweyo iya kuba neempawu ezingaphelelanga.

Kukho iinkcukacha ezininzi kunye neemfuno kuyilo PCB isilika screen, kwaye zezi nkcukacha ezikhuthaza uphuhliso PCB iteknoloji yoshicilelo screen.