Isikrini sikasilika se-PCBukuphrinta kuyinqubo ebalulekile ekukhiqizeni amabhodi wesifunda we-PCB, okunquma izinga lebhodi le-PCB eliphelile.Ukwakhiwa kwebhodi lesifunda se-PCB kuyinkimbinkimbi kakhulu.Kunemininingwane eminingi emincane enqubweni yokuklama.Uma ingaphathwa kahle, izothinta ukusebenza kwebhodi le-PCB lonke.Ukuze kwandiswe ukusebenza kahle kwedizayini kanye nekhwalithi yomkhiqizo, yiziphi izinkinga okufanele sizinake ngesikhathi sokuklama?

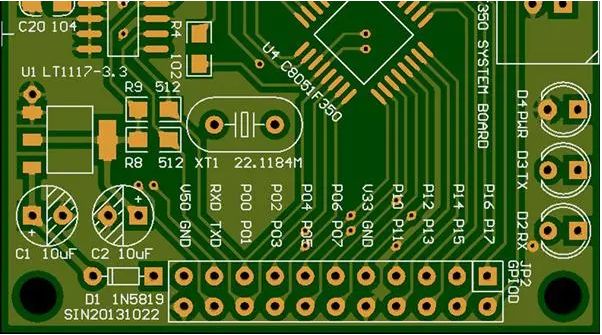

Ihluzo zomlingiswa zakhiwa ebhodini le-pcb ngesikrini sikasilika noma ukuphrinta kwe-inkjet.Umlingiswa ngamunye umele ingxenye ehlukile futhi udlala indima ebaluleke kakhulu ekwakhiweni kwakamuva.

Ake ngethule abalingisi abavamile.Ngokuvamile, u-C umele i-capacitor, u-R umele ukuphikiswa, u-L umele i-inductor, u-Q umele i-transistor, u-D umele i-diode, u-Y umele i-crystal oscillator, u-U umele i-integrated circuit, B imele i-buzzer, T imele i-transistor, K. imele i-Relays nokunye.

Ebhodini lesifunda, sivame ukubona izinombolo ezifana no-R101, C203, njll. Eqinisweni, uhlamvu lokuqala lumelele isigaba sengxenye, inombolo yesibili ikhomba inombolo yokusebenza kwesekhethi, kanti izinombolo zesithathu nesine zimelela inombolo ye-serial kusekhethi. ibhodi.Ngakho-ke siqonda kahle ukuthi i-R101 iyisivimbeli sokuqala kumjikelezo wokuqala osebenzayo, futhi i-C203 iyi-capacitor yesithathu kumjikelezo wokusebenza kwesibili, ukuze ukuhlonza uhlamvu kube lula ukukuqonda.

Eqinisweni, izinhlamvu ezisebhodini lesifunda le-PCB yilokho esivame ukukubiza ngokuthi isikrini sikasilika.Into yokuqala abathengi abayibonayo lapho bethola ibhodi le-PCB isikrini sikasilika kuso.Ngezinhlamvu zesikrini sikasilika, bangaqonda ngokucacile ukuthi yiziphi izingxenye okufanele zibekwe endaweni ngayinye ngesikhathi sokufakwa.Kulula ukuhlanganisa isichibi nokulungisa.Ngakho-ke yiziphi izinkinga okufanele zinakwe kunqubo yokuklama yokuphrinta isikrini sikasilika?

1) Ibanga phakathi kwesikrini sikasilika nephedi: isikrini sikasilika asikwazi ukubekwa phezu kwephedi.Uma iphedi imbozwe isikrini sikasilika, izoba nomthelela ekuhlanganisweni kwezingxenye, ngakho-ke isikhala esingu-6-8mil kufanele sibekelwe.2) Ububanzi bokuphrinta kwesikrini: Ububanzi bomugqa wokuphrinta kwesikrini ngokuvamile bungaphezu kuka-0.1mm (4 mill), okusho ububanzi bukayinki.Uma ububanzi bomugqa buncane kakhulu, uyinki ngeke uphume esikrinini sokuphrinta, futhi izinhlamvu zingakwazi ukuphrinta.3) Ubude bezinhlamvu zokuphrinta isikrini sikasilika: Ubude bezinhlamvu ngokuvamile bungaphezu kuka-0.6mm (25mil).Uma ubude bezinhlamvu bungaphansi kuka-25mil, izinhlamvu eziphrintiwe ngeke zicace futhi zifiphaliswe kalula.Uma umugqa wezinhlamvu ushubile kakhulu noma ibanga liseduze kakhulu, kuzodala ukufiphala.

4) Isiqondiso sokuphrinta kwesikrini sikasilika: ngokuvamile landela isimiso sokusuka kwesobunxele kuye kwesokudla futhi kusukela phansi kuya phezulu.

5) Incazelo ye-polarity: Izingxenye ngokuvamile zine-polarity.Idizayini yokuphrinta isikrini kufanele inake ukumaka izigxobo ezinhle nezingezinhle kanye nezingxenye eziqondisayo.Uma izigxobo ezinhle nezingezinhle zihlehliswa, kulula ukubangela isifunda esifushane, okwenza ibhodi lesifunda lishise futhi alikwazi ukumbozwa.

6) Ukuhlonza iphinikhodi: Ukuhlonza iphini kungahlukanisa isiqondiso sezingxenye.Uma izinhlamvu zesikrini sikasilika zimaka ukuhlonza ngokungalungile noma kungekho ukuhlonza, kulula ukubangela ukuthi izingxenye zifakwe ngokuhlehla.

7) Isimo sesikrini sikasilika: Ungabeki umklamo wesikrini sikasilika embotsheni ebhoboziwe, ngaphandle kwalokho ibhodi le-pcb eliphrintiwe lizoba nezinhlamvu ezingaphelele.

Kukhona ukucaciswa okuningi kanye nezidingo zokwakheka kwesikrini sikasilika se-PCB, futhi yilezi zicaciso ezikhuthaza ukuthuthukiswa kobuchwepheshe bokuphrinta isikrini se-PCB.