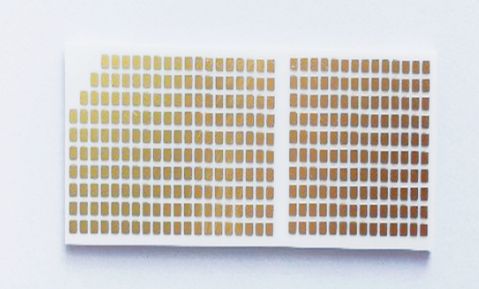

Ukutywinwa komngxuma we-Electroplated yinkqubo yokuvelisa ibhodi yesekethe eprintiweyo eqhelekileyo esetyenziselwa ukuzalisa kunye nokutywinwa kwimingxuma (ngemingxuma) ukunyusa ukuhanjiswa kombane kunye nokukhusela.Kwinkqubo yokuvelisa ibhodi yesekethe eprintiweyo, i-pass-through hole ngumjelo osetyenziselwa ukudibanisa iileyile zeesekethe ezahlukeneyo.Injongo yokutywinwa kwe-electroplating kukwenza udonga lwangaphakathi lomngxuma olugcwele izinto zokuqhuba ngokwenza umaleko wesinyithi okanye ukubekwa kwezinto eziqhutywayo ngaphakathi kumngxuma odlulayo, ngaloo ndlela kuphuculwa ukuqhutywa kombane kunye nokubonelela ngesiphumo esingcono sokutywinwa.

I-1. Inkqubo yokutywinwa kwebhodi ye-electroplating izise iingenelo ezininzi kwinkqubo yokuvelisa imveliso:

a) Ukuphucula ukuthembeka kwesekethe: inkqubo yebhodi yesekethe yokutywinwa kwe-electroplating inokuvala ngokufanelekileyo imingxuma kwaye ithintele isiphaluka esifutshane sombane phakathi kweengqimba zetsimbi kwibhodi yesekethe.Oku kunceda ukuphucula ukuthembeka kunye nokuzinza kwebhodi kunye nokunciphisa umngcipheko wokungaphumeleli kwesiphaluka kunye nomonakalo

b)Ukuphucula ukusebenza kwesekethe: Ngenkqubo yokutywinwa kwe-electroplating, uqhagamshelo olungcono lwesekethe kunye nokuhanjiswa kombane kunokufezekiswa.Umngxuma wokuzalisa i-Electroplate unokubonelela ngonxibelelwano lwesekethe oluzinzile kunye noluthembekileyo, ukunciphisa ingxaki yokulahleka komqondiso kunye nokungahambi kakuhle kwe-impedance, kwaye ngaloo ndlela kuphuculwe amandla okusebenza kwesekethe kunye nemveliso.

c) Ukuphucula umgangatho we-welding: inkqubo yebhodi yesekethe yokutywinwa kwe-electroplating inokuphucula umgangatho we-welding.Inkqubo yokutywinwa inokudala indawo ethe tyaba, egudileyo ngaphakathi komngxuma, ibonelela ngesiseko esingcono sokuwelda.Oku kunokuphucula ukuthembeka kunye namandla e-welding kunye nokunciphisa ukuvela kweziphene ze-welding kunye neengxaki ze-welding ezibandayo.

d)Qinisa amandla omatshini: Inkqubo yokutywinwa kwe-electroplating inokuphucula amandla omatshini kunye nokuqina kwebhodi yesekethe.Ukuzalisa imingxuma kunokunyusa ubukhulu kunye nokuqina kwebhodi yesiphaluka, ukuphucula ukuchasana kwayo ukugoba kunye nokugubha, kunye nokunciphisa umngcipheko wokulimala komatshini kunye nokuphuka ngexesha lokusetyenziswa.

e) Indibano elula kunye nokufakwa: inkqubo yokutywinwa kwebhodi yesekethe ye-electroplating inokwenza ukuba indibano kunye nenkqubo yofakelo ibe lula kwaye isebenze.Ukuzalisa imingxuma kunika indawo ezinzileyo kunye namanqaku okudibanisa, okwenza ukufakwa kwendibano kube lula kwaye kuchaneke ngakumbi.Ukongezelela, ukutywinwa komngxuma we-electroplated kunika ukhuseleko olungcono kunye nokunciphisa umonakalo kunye nokulahlekelwa kwamacandelo ngexesha lofakelo.

Ngokubanzi, inkqubo yokutywinwa kwebhodi yesekethe ye-electroplating inokuphucula ukuthembeka kwesekethe, iphucule ukusebenza kwesekethe, iphucule umgangatho we-welding, iqinise amandla oomatshini, kwaye iququzelele indibano kunye nofakelo.Ezi zibonelelo zinokuphucula kakhulu umgangatho wemveliso kunye nokuthembeka, ngelixa ukunciphisa umngcipheko kunye neendleko kwinkqubo yokuvelisa

2.Nangona inkqubo yokutywinwa kwebhodi yesekethe ye-electroplating ineengenelo ezininzi, kukwakho ezinye iingozi ezinokubakho okanye iintsilelo, kubandakanya oku kulandelayo:

f) Iindleko ezongeziweyo: Inkqubo yokutywinwa komngxuma webhodi idinga iinkqubo ezongezelelweyo kunye nezixhobo, ezifana nokuzalisa izinto kunye neekhemikhali ezisetyenziselwa inkqubo yokubeka.Oku kunokunyusa iindleko zokuvelisa kwaye kube nefuthe kuqoqosho jikelele lwemveliso

g) Ukuthembeka kwexesha elide: Nangona inkqubo yokutywinwa kwe-electroplating inokuphucula ukuthembeka kwebhodi yesiphaluka, kwimeko yokusetyenziswa kwexesha elide kunye nokutshintsha kwendalo, izinto zokuzalisa kunye nokugubungela kunokuchaphazeleka ngezinto ezifana nokwandiswa kwe-thermal kunye nokubanda. ukufinyela, ukufuma, umhlwa njalo njalo.Oku kunokukhokelela kwimpahla yokuzalisa ekhululekile, ukuwa, okanye umonakalo kwiplating, ukunciphisa ukuthembeka kwebhodi.

h)3Ubunzima benkqubo: Inkqubo yokutywinwa kwebhodi yesekethe ye-electroplating inzima kunenkqubo eqhelekileyo.Kubandakanya ukulawulwa kwamanyathelo amaninzi kunye neeparitha ezifana nokulungiswa komngxuma, ukuzaliswa kwezinto eziphathekayo kunye nokwakhiwa, ulawulo lwenkqubo ye-electroplating, njl. Oku kunokufuna izakhono zenkqubo ephezulu kunye nezixhobo zokuqinisekisa ukuchaneka kwenkqubo nokuzinza.

i) Yandisa inkqubo: yandisa inkqubo yokutywinwa, kwaye yandise ifilimu yokuvala imingxunya emikhudlwana ukuqinisekisa isiphumo sokutywinwa.Emva kokutywinwa komngxuma, kuyimfuneko ukuhlamba ubhedu, ukugaya, ukupolisha kunye namanye amanyathelo okuqinisekisa ukunyameka kwendawo yokutywina.

j)Impembelelo yokusingqongileyo: Iikhemikhali ezisetyenziswa kwinkqubo yokutywinwa kwe-electroplating inokuba nefuthe elithile kokusingqongileyo.Umzekelo, amanzi amdaka kunye nenkunkuma engamanzi inokuveliswa ngexesha le-electroplating, efuna unyango olufanelekileyo kunye nonyango.Ukongezelela, kunokubakho amacandelo anobungozi bokusingqongileyo kwizinto zokuzalisa ezifuna ukulawulwa ngokufanelekileyo kwaye zilahlwe.

Xa kuqwalaselwa inkqubo yokutywinwa kwebhodi yesekethe ye-electroplating, kuyimfuneko ukuqwalasela ngokubanzi ezi bungozi okanye iintsilelo ezinokubakho, kwaye ulinganise iinzuzo kunye neengxaki ngokweemfuno ezithile kunye neemeko zesicelo.Xa kuphunyezwa inkqubo, ulawulo olufanelekileyo lomgangatho kunye namanyathelo olawulo lokusingqongileyo kubalulekile ukuze kuqinisekiswe iziphumo zenkqubo engcono kunye nokuthembeka kwemveliso.

3.Imigangatho yokwamkelwa

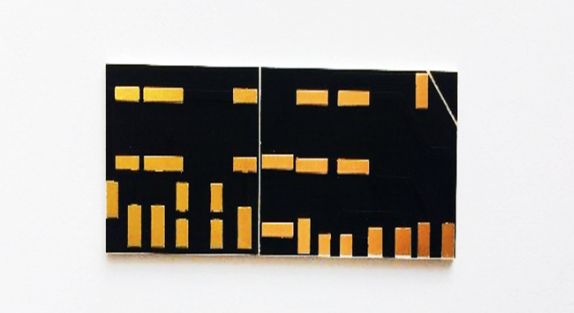

Ngokomgangatho: IPC-600-J3.3.20: Electroplated copper plug microconduction (imfama kwaye ingcwatywe)

I-Sag kunye ne-bulge: Iimfuno ze-bulge (iqhuma) kunye nokudakumba (umngxuma) womngxuma ongaboniyo uya kumiselwa ngamaqela obonelelo kunye nebango ngothethathethwano, kwaye akukho mfuneko yeqhuma kunye nokudakumba kwemicro exakekileyo. -ngomngxuma wobhedu.Amaxwebhu athile okuthengwa kwabathengi okanye imigangatho yomthengi njengesiseko somgwebo.