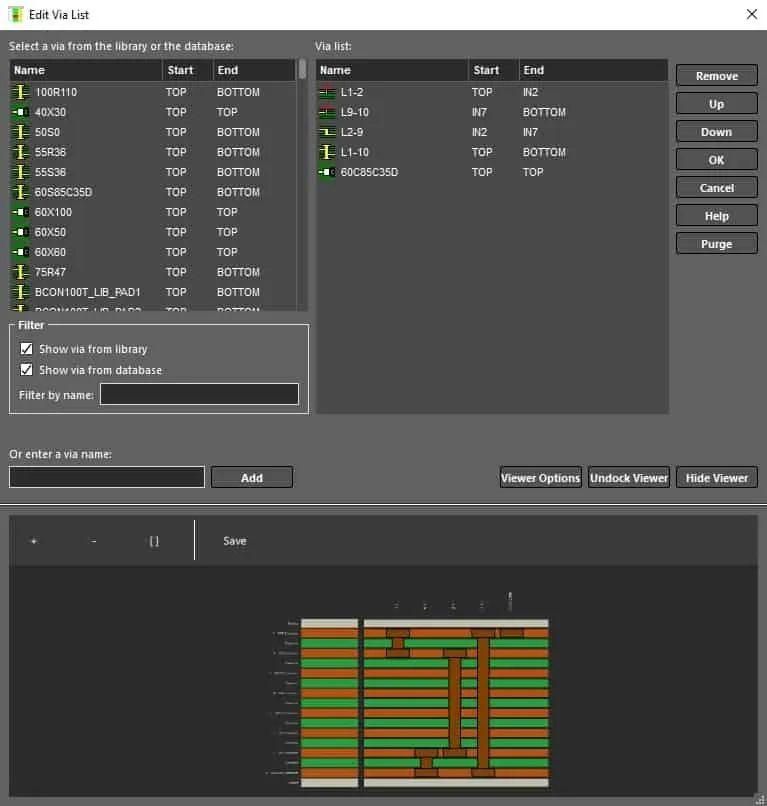

Kanye njengokuba iivenkile ze-hardware kufuneka zilawule kwaye zibonise izikhonkwane kunye nezikrufu zeentlobo ezahlukeneyo, i-metric, impahla, ubude, ububanzi kunye ne-pitch, njl.Uyilo lwePCB lweSintu lunokusebenzisa kuphela imingxunya embalwa eyahlukeneyo yokupasa, kodwa uyilo lwanamhlanje olunoxinano oluphezulu (HDI) lufuna iindidi ezininzi ezahlukeneyo kunye nobukhulu bemingxuma yokupasa.Umngxuma ngamnye wokupasa kufuneka ulawulwe ukuba usetyenziswe ngokuchanekileyo, uqinisekisa ukusebenza kwebhodi ephezulu kunye nokwenziwa kweempazamo.Eli nqaku liza kucacisa imfuneko yokulawula ukuxinana okuphezulu ngemingxuma kuyilo lwePCB kunye nendlela yokuphumeza oku.

Izinto eziqhuba uyilo lwePCB yoxinaniso oluphezulu

Njengoko imfuno yezixhobo zombane ezincinci iqhubeka ikhula, iibhodi zesekethe eziprintiweyo ezinika amandla ezi zixhobo kufuneka zicuthe ukuze zingene kuzo.Ngexesha elifanayo, ukwenzela ukuhlangabezana neemfuno zokuphucula ukusebenza, izixhobo zombane kufuneka zongeze izixhobo ezininzi kunye neesekethe ebhodini.Ubungakanani bezixhobo ze-PCB buhlala buncipha, kwaye inani lezikhonkwane liyanda, ngoko kufuneka usebenzise izikhonkwane ezincinci kunye nezithuba ezikufutshane ukuyila, okwenza ingxaki ibe nzima ngakumbi.Kubaqulunqi bePCB, oku kukulingana nebhegi incinci kwaye incinci, ngelixa ibambe izinto ezininzi kuyo.Iindlela zemveli zoyilo lwebhodi yesekethe ngokukhawuleza zifikelela kwimida yazo.

Ukuze kuhlangatyezwane nesidingo sokongeza iisekethe ezininzi kwisayizi yebhodi encinci, indlela entsha yoyilo yePCB yavela - i-high-density Interconnect, okanye i-HDI.Uyilo lwe-HDI lusebenzisa ubuchule bokuvelisa ibhodi yesekethe engaphezulu, ububanzi bemigca emincinci, izixhobo ezibhityileyo, kunye ne-microholes engaboniyo kunye nokungcwatywa okanye i-laser-drilled.Ngombulelo kwezi mpawu zoxinaniso oluphezulu, iisekethe ezininzi zinokufakwa kwibhodi encinci kwaye zinike isisombululo soxhulumaniso esisebenzayo kwiisekethe ezidibeneyo ezininzi.

Kukho ezinye iingenelo ezininzi zokusebenzisa le mingxunya exinene kakhulu:

Iitshaneli zocingo:Ekubeni imingxuma eyimfama kunye nengcwaba kunye ne-microholes ayingeni kwi-stack layer, oku kudala iziteshi zocingo ezongezelelweyo kuyilo.Ngokubeka ngobuchule le mingxunya yahlukeneyo, abaqulunqi banokufaka izixhobo zocingo kunye namakhulu ezikhonkwane.Ukuba kusetyenziswe imingxunya esemgangathweni kuphela, izixhobo ezinezikhonkwane ezininzi ziya kuvala onke amajelo ocingo angaphakathi.

Ingqibelelo yoMqondiso:Iimpawu ezininzi kwizixhobo zombane ezincinci zineemfuno ezithile zemfezeko yomqondiso, kwaye imingxunya edlulayo ayihlangabezani neemfuno zoyilo.Le mingxuma inokwenza i-eriyali, ingenise iingxaki ze-EMI, okanye ichaphazele indlela yokubuyisela umqondiso wothungelwano olubalulekileyo.Ukusetyenziswa kwemingxuma eyimfama kunye nokungcwatywa okanye i-microholes kuphelisa iingxaki ezinokuthi zibe khona zengqibelelo yomqondiso obangelwa ukusetyenziswa kwemingxuma.

Ukuqonda ngcono le mingxunya, makhe sijonge kwiindidi ezahlukeneyo zemingxuma enokuthi isetyenziswe kuyilo oluxinana kakhulu kunye nokusetyenziswa kwayo.

Uhlobo kunye nolwakhiwo lwemingxuma yoqhagamshelo oluphezulu

Umngxuma wokudlula ngumngxuma kwibhodi yesekethe edibanisa iileya ezimbini okanye ngaphezulu.Ngokubanzi, umngxuma uhambisa umqondiso oqhutywe yisekethe ukusuka kwelinye ibhodi lebhodi ukuya kwisiphaluka esihambelanayo kwelinye inqanaba.Ukuze kuqhutywe imiqondiso phakathi kwee-wiring layers, imingxuma ifakwe isinyithi ngexesha lokuvelisa.Ngokutsho kokusetyenziswa okuthe ngqo, ubukhulu bomngxuma kunye nephedi bahluke.Imingxunya emincinci isetyenziselwa ukwenza iintambo zomqondiso, ngelixa imingxuma emikhulu isetyenziselwa amandla kunye neengcingo zomhlaba, okanye ukunceda izixhobo zokufudumeza ubushushu.

Iindidi ezahlukeneyo zemingxuma kwibhodi yesekethe

ngomngxuma

Umngxuma wokutyhutyha ngumgangatho wokutyhutyha oye wasetyenziswa kwiibhodi zeesekethe ezinamacala amabini ukususela oko zaziswa okokuqala.Imingxuma igrunjwa ngoomatshini kuyo yonke ibhodi yesekethe kwaye i-electroplated.Nangona kunjalo, ubuncinci bobuncinci obunokuthi buqhutywe yi-drill mechanical bunemida ethile, kuxhomekeke kumlinganiselo we-aspect ratio ye-drill diameter ukuya kwi-plate thickness.Ngokuqhelekileyo, ukuvuleka komngxuma odlulayo akukho ngaphantsi kwe-0.15 mm.

Umngxuma oyimfama:

Njengemingxuma, imingxuma igrunjwa ngoomatshini, kodwa ngamanyathelo okuvelisa angaphezulu, inxenye yepleyiti igrunjwa ukusuka phezulu.Imingxuma eyimfama nayo ijongene nengxaki yokulinganiselwa kobungakanani besuntswana;Kodwa kuxhomekeke ukuba sikweliphi na icala lebhodi, sinokufaka ucingo ngaphezulu okanye ngaphantsi komngxuma oyimfama.

Umngxuma ongcwatywe:

Imingxuma engcwatyiweyo, njengemingxuma engaboniyo, igrunjwa ngoomatshini, kodwa iqala kwaye iphele kumaleko angaphakathi ebhodi kunomphezulu.Lo mngxuma wokutyhutyha kwakhona ufuna amanyathelo okwenziwa okongeziweyo ngenxa yesidingo sokuzinziswa kwisitaki sepleyiti.

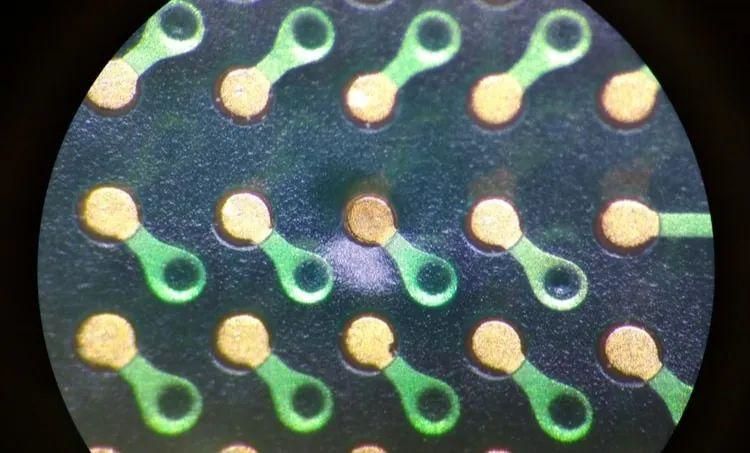

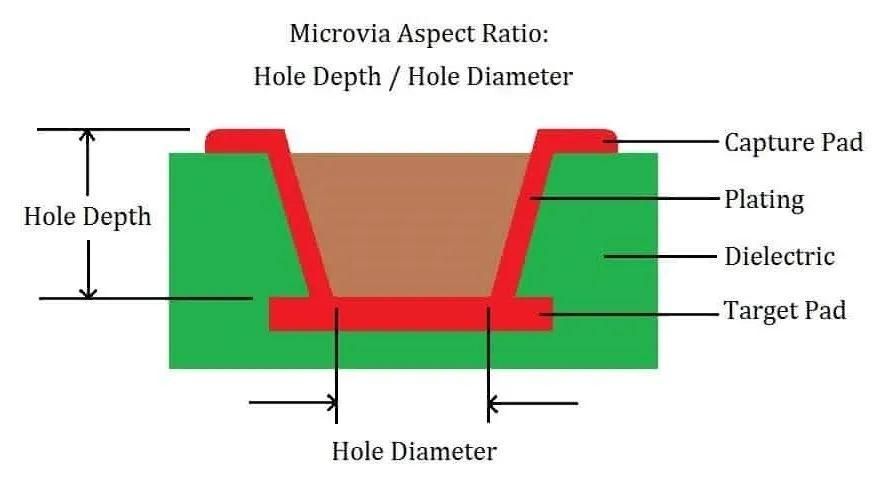

I-Micropore

Oku kugqobhoza kukhutshwe nge-laser kwaye i-aperture ingaphantsi komda we-0.15 mm we-drill bit mechanical bit.Ngenxa yokuba i-microholes ithatha kuphela imigangatho emibini emeleneyo yebhodi, umyinge we-aspect ratio yenza imingxunya ifumaneke ngokutyalwa incinci kakhulu.I-Microholes nayo inokubekwa phezu komhlaba okanye ngaphakathi kwebhodi.Imikrolo emincinci idla ngokuzaliswa kwaye icwecwe, ifihliwe ngokusisiseko, kwaye ke ngoko inokubekwa kumphezulu-wento iibhola zesodare zamacandelo anje ngoluhlu lwegridi yebhola (BGA).Ngenxa ye-aperture encinci, i-pad efunekayo kwi-microhole nayo incinci kakhulu kunomngxuma oqhelekileyo, malunga ne-0.300 mm.

Ngokweemfuno zokuyila, ezi ntlobo zemingxuma zingentla apha zinokulungiswa ukuze zisebenze kunye.Ngokomzekelo, i-micropores inokufakwa kunye nezinye ii-micropores, kunye nemingxuma engcwatywe.Le mingxuma nayo inokugxadanyiswa.Njengoko bekutshiwo ngaphambili, ii-microholes zinokufakwa kwiipadi ezinezikhonkwane zento engaphezulu.Ingxaki yokuxinana kweengcingo iye yancitshiswa ngakumbi ngokungabikho kwendlela yemveli ukusuka kwindawo yokubeka umphezulu ukuya kwindawo yokuphuma kwefeni.