1. PCB through hole plating

There are many ways to build a layer of plating that meets the requirements on the hole wall of the substrate. This is called hole wall activation in industrial applications. Its PCB board manufacturers use multiple intermediate storage tanks in the production process. Each storage tank The tank has its own control and maintenance requirements. Through-hole electroplating is the subsequent necessary manufacturing process of the drilling process. When the drill bit drills through the copper foil and the substrate below, the heat generated melts the insulating synthetic resin that forms the base of most substrates, the molten resin and other drilling fragments It is deposited around the hole and coated on the newly exposed hole wall in the copper foil, which is actually harmful to the subsequent plating surface.

The molten resin will also leave a layer of hot axis on the hole wall of the substrate, which shows poor adhesion to most activators, which requires the development of a class of techniques similar to stain removal and etchback chemistry. One method that is more suitable for the prototype of printed circuit boards is to use a specially designed low-viscosity ink to form a highly adhesive and highly conductive coating on the inner wall of each through hole. In this way, there is no need to use multiple chemical treatment processes, only one application step, followed by thermal curing, can form a continuous coating on the inside of all the hole walls, it can be directly electroplated without further treatment. This ink is a resin-based substance that has strong adhesion and can be easily bonded to most thermally polished hole walls, thus eliminating the step of etch back.

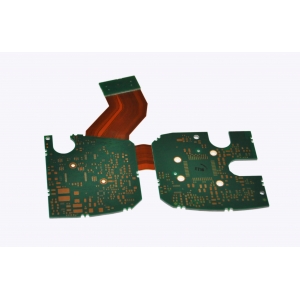

2. Reel linkage type selective plating

The pins and pins of electronic components, such as connectors, integrated circuits, transistors, and flexible FPCB boards, are all plated to obtain good contact resistance and corrosion resistance. This electroplating method can be manual or automatic, and it is very expensive to select each pin individually for plating, so mass welding must be used. Usually, the two ends of the metal foil rolled to the required thickness are punched, cleaned by chemical or mechanical methods, and then selectively selected like nickel, gold, silver, rhodium, button or tin-nickel alloy, copper-nickel alloy , Nickel-lead alloy, etc. for continuous plating. In the electroplating method of selective plating, first of all, a layer of resist film is coated on the part of the metal copper foil plate that does not need to be plated, and only the selected copper foil part is plated.

3. Finger-plating plating

The rare metal needs to be plated on the board edge connector, the board edge protruding contact or the gold finger to provide lower contact resistance and higher wear resistance. This technique is called finger row plating or protruding part plating. Gold is often plated on the protruding contacts of the edge connector with nickel plating on the inner layer. The gold finger or the protruding part of the edge of the board uses manual or automatic plating technology. At present, the gold plating on the contact plug or gold finger has been plated with grandmother and lead , Plated buttons instead.

The process is as follows:

1. Strip the coating to remove the tin or tin-lead coating on the protruding contacts.

2. Rinse with washing water.

3. Scrub with abrasives.

4. Activation is submerged in 10% sulfuric acid.

5. The thickness of nickel plating on the protruding contacts is 4-5μm.

6. Wash and remove mineral water.

7. Treatment of gold penetration solution.

8. Gold plating.

9. Cleaning.

10. Drying.

4. Brush plating

It is an electrodeposition technique, and not all parts are immersed in the electrolyte during the electroplating process. In this electroplating technique, only a limited area is electroplated, and it has no effect on the rest. Usually, rare metals are plated on selected parts of the printed circuit board, such as areas such as board edge connectors. Brush plating is used more often in the repair of waste circuit boards in electronic assembly shops. Wrap a special anode (anode that is chemically inactive, such as graphite) in an absorbent material (cotton swab) and use it to bring the plating solution to the place where plating is needed.

Fastline Circuits Co.,Limited is a professional: PCB circuit board manufacturing manufacturer, providing you with: PCB proofing, batch system board, 1-34 layer PCB board, high TG board, impedance board, HDI board, Rogers board, Manufacture and production of PCB circuit boards of various processes and materials such as microwave boards, radio frequency boards, radar boards, thick copper foil boards, etc.