A cikin ƙirar hukumar PCB, ƙirar anti-ESD na PCB za a iya cimma ta hanyar shimfidawa, shimfidar wuri mai kyau da wayoyi da shigarwa.A lokacin aikin ƙira, yawancin gyare-gyaren ƙira na iya iyakancewa ga ƙarawa ko rage abubuwan da aka haɗa ta hanyar tsinkaya.Ta hanyar daidaita shimfidar PCB da wayoyi, ana iya hana ESD da kyau.

Wutar lantarki ta PCB daga jikin mutum, muhalli har ma da na'urorin hukumar PCB na lantarki za su haifar da lahani iri-iri ga madaidaicin guntuwar semiconductor, kamar shigar da sikirin insulation Layer a cikin sashin;Lalacewa ga ƙofar MOSFET da abubuwan CMOS;CMOS PCB kwafin makullin jawo;PN junction tare da gajeriyar juyawa baya;Gudun kwafin kwafin PCB na gajeren lokaci don daidaita mahadar PN;Takardar PCB tana narkar da waya mai siyar ko wayar aluminium a cikin takardar PCB na na'urar aiki.Don kawar da tsangwama na fitarwa na lantarki (ESD) da lalata kayan lantarki, ya zama dole a dauki matakan fasaha iri-iri don hanawa.

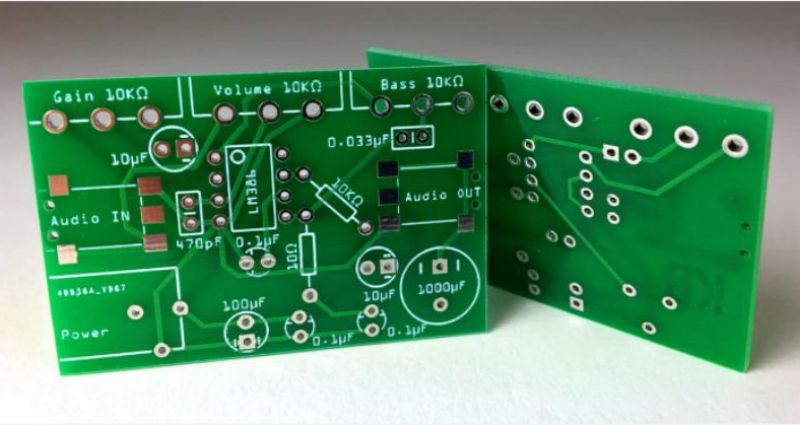

A cikin ƙirar hukumar PCB, ƙirar anti-ESD na PCB za a iya cimma ta hanyar shimfidawa da shimfidar tsarin wayar PCB da shigarwa.A lokacin aikin ƙira, yawancin gyare-gyaren ƙira na iya iyakancewa ga ƙarawa ko rage abubuwan da aka haɗa ta hanyar tsinkaya.Ta hanyar daidaita shimfidar PCB da kewayawa, za a iya hana PCB kwafin hukumar da kyau daga PCB kwafin hukumar ESD.Ga wasu matakan kiyayewa na gama gari.

Yi amfani da yadudduka da yawa na PCB gwargwadon yiwuwa, idan aka kwatanta da PCB mai gefe biyu, jirgin ƙasa da jirgin sama mai ƙarfi, da kuma tazarar layin ƙasa da aka tsara a hankali na iya rage ƙarancin yanayin gama gari da haɗa haɗin gwiwa, ta yadda zai iya kaiwa 1. /10 zuwa 1/100 na PCB mai gefe biyu.Gwada sanya kowane siginar sigina kusa da madaurin wuta ko ƙasa.Don PCBS mai girma wanda ke da abubuwan haɗin gwiwa a saman sama da ƙasa, suna da gajerun layin haɗi da wuraren cika da yawa, zaku iya la'akari da yin amfani da layin ciki.Don PCBS mai gefe biyu, ana amfani da wutar lantarki da aka haɗa tare da grid na ƙasa.Kebul na wutar lantarki yana kusa da ƙasa, tsakanin layi na tsaye da a kwance ko wuraren cikawa, don haɗawa gwargwadon yiwuwa.Daya gefen grid PCB takardar size ne kasa ko daidai da 60mm, idan zai yiwu, da grid size ya zama kasa da 13mm.

Tabbatar cewa kowace takardar PCB ta da'ira tana da ƙanƙanta gwargwadon yiwuwa.

Ajiye duk masu haɗin kai a gefe gwargwadon yiwuwa.

Idan za ta yiwu, gabatar da layin tsiri na PCB daga tsakiyar katin kuma nesa da wuraren da ke da saukin kamuwa da tasirin ESD kai tsaye.

A kan duk yadudduka na PCB da ke ƙasa masu haɗin haɗin da ke fitowa daga cikin chassis (waɗanda ke da saurin lalata ESD ga allon kwafin PCB), sanya faffadan chassis ko polygon cika benaye kuma haɗa su tare da ramuka a tazarar kusan 13mm.

Sanya ramukan hawa na PCB a gefen katin, sa'annan ku haɗa saman saman da ƙasan fakitin PCB maras shinge kewaye da ramukan hawa zuwa ƙasa na chassis.

Lokacin haɗa PCB, kar a shafa kowane mai siyar a saman ko ƙasan takardar PCB.Yi amfani da sukurori tare da ginanniyar kayan wanki na PCB don samun madaidaicin lamba tsakanin takardar/garkuwar PCB a cikin akwati na ƙarfe ko goyan bayan saman ƙasa.

Ya kamata a saita "yankin ware" iri ɗaya tsakanin ƙasan chassis da kewayen kowane Layer;Idan zai yiwu, kiyaye tazarar a 0.64mm.

A sama da kasa na katin kusa da PCB kwafin allon hawa ramukan, haɗa chassis da kewayen ƙasa tare da faɗin wayoyi 1.27mm tare da wayar ƙasan chassis kowane 100mm.Kusa da waɗannan wuraren haɗin, ana sanya pad ɗin solder ko ramukan hawa don shigarwa tsakanin bene na chassis da takaddar PCB na kewaye.Ana iya yanke waɗannan haɗin ƙasa buɗe tare da ruwan wukake don kasancewa a buɗe, ko tsalle tare da ƙwanƙolin maganadisu/maɗaukakin mitar mai ƙarfi.

Idan da'irar hukumar ba za a sanya a cikin wani karfe hali ko PCB takardar garkuwa na'urar, kada ku yi amfani da solder juriya zuwa sama da kasa harka grounding wayoyi na kewaye hukumar, sabõda haka, za a iya amfani da su a matsayin ESD baka sallama electrodes.

Don saita zobe a kewayen da'ira a jere na PCB mai zuwa:

(1) Baya ga gefen na'urar kwafin PCB da chassis, sanya hanyar zobe kewaye da kewayen waje gaba ɗaya.

(2) Tabbatar cewa duk yadudduka sun fi faɗin 2.5mm.

(3) Haɗa zoben da ramuka kowane 13mm.

(4)Haɗa filin zobe zuwa ga gama gari na da'irar kwafin PCB mai yawan Layer Layer.

(5) Don fakitin PCB mai gefe biyu da aka sanya a cikin shingen ƙarfe ko na'urorin kariya, ya kamata a haɗa ƙasan zobe zuwa filin gama gari.Ya kamata a haɗa da'irar mai gefe biyu mara kariya zuwa ƙasan zobe, ƙasan zobe ba za a iya rufe shi da juriya na solder ba, ta yadda zoben zai iya aiki azaman sandar fitarwa na ESD, kuma aƙalla an sanya rata mai faɗi 0.5mm a wani takamaiman. matsayi a kan ƙasan zobe (duk yadudduka), wanda zai iya guje wa PCB kwafin allo don samar da babban madauki.Nisa tsakanin siginar siginar da ƙasan zobe bai kamata ya zama ƙasa da 0.5mm ba.