Kuyilo loyilo lwePCB, uyilo lwamacandelo lubalulekile, olumisela idigri ecocekileyo nentle yebhodi kunye nobude kunye nobungakanani bocingo oluprintiweyo, kwaye lunempembelelo ethile ekuthembekeni komatshini wonke.

Ibhodi yesekethe elungileyo, ukongeza ekuphunyezweni komgaqo womsebenzi, kodwa kwakhona ukuqwalasela i-EMI, i-EMC, i-ESD (i-electrostatic discharge), ingqibelelo yomqondiso kunye nezinye iimpawu zombane, kodwa kwakhona ukuqwalasela isakhiwo somatshini, iingxaki ezinkulu zokutshatyalaliswa kobushushu be-chip.

Iimfuno zenkcazo yoyilo ngokubanzi lwePCB

1, funda uxwebhu lwenkcazo yoyilo, ukuhlangabezana nesakhiwo esikhethekileyo, imodyuli ekhethekileyo kunye nezinye iimfuno zokubeka.

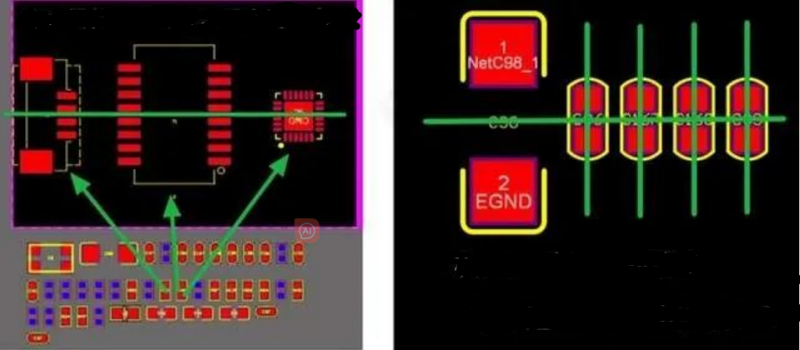

I-2, setha indawo yegridi yoyilo kwi-25mil, inokulungelelaniswa ngendawo yegridi, izithuba ezilinganayo; Imo yokulungelelanisa inkulu phambi kokuba incinci (izixhobo ezinkulu kunye nezixhobo ezinkulu zilungelelaniswe kuqala), kwaye imo yokulungelelanisa iphakathi, njengoko kubonisiwe kulo mfanekiso ulandelayo.

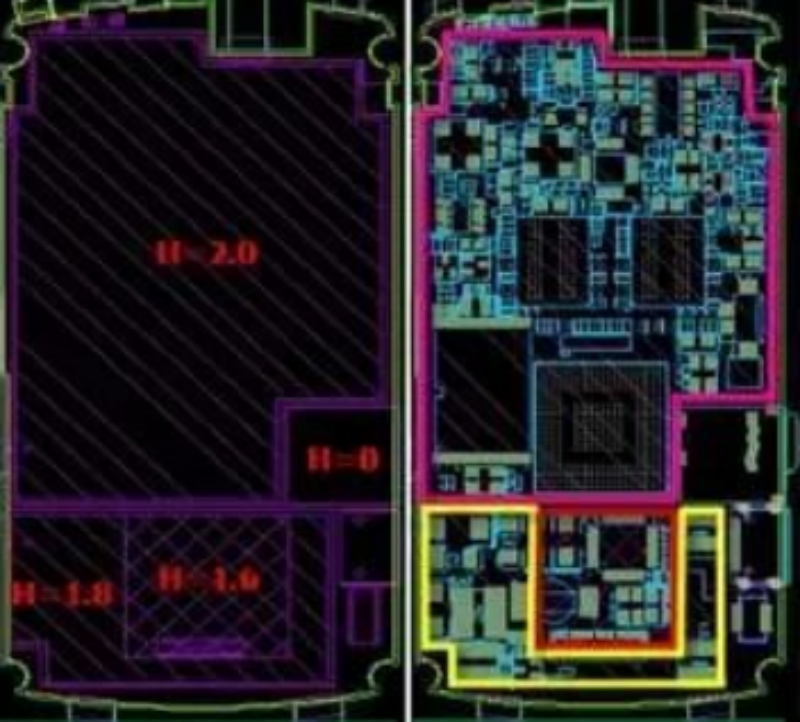

3, ukuhlangabezana nomda wobude obungavumelekanga, ubume kunye noyilo lwesixhobo esikhethekileyo, iimfuno zendawo ezingavumelekanga.

① Umzobo 1 (ekhohlo) ngezantsi: Iimfuno zomda wobude, eziphawulwe ngokucacileyo kumatshini okanye umaleko wokumakisha, olungele ukutshekishwa kamva;

(2) Phambi koyilo, seta indawo enqatshelweyo, efuna ukuba isixhobo sibe yi-5mm kude nomphetho webhodi, musa ukuyila isixhobo, ngaphandle kokuba iimfuno ezikhethekileyo okanye uyilo lwebhodi olulandelayo lunokongeza umphetho wenkqubo;

③ Uyilo lwesakhiwo kunye nezixhobo ezizodwa zinokubekwa ngokuchanekileyo ngolungelelwaniso okanye ngolungelelwaniso lwesakhelo sangaphandle okanye umgca ophakathi wamacandelo.

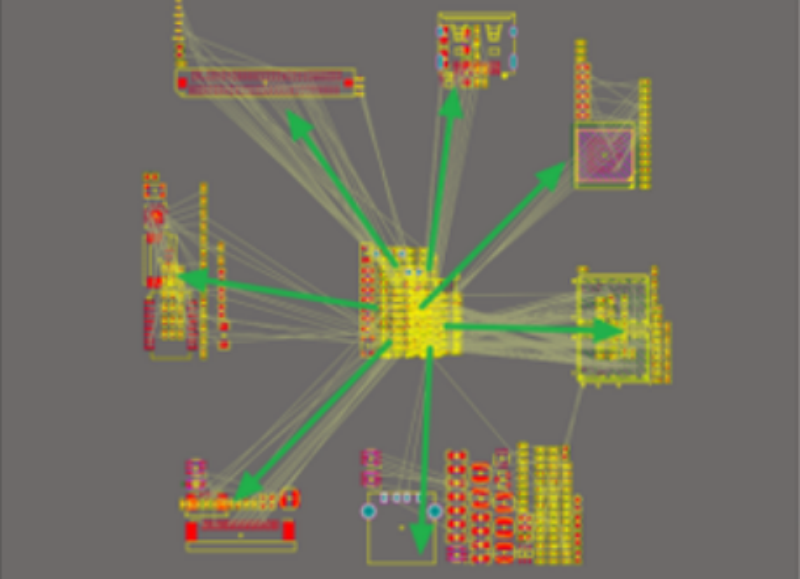

I-4, i-layout kufuneka ibe ne-pre-layout kuqala, musa ukufumana ibhodi ukuba iqalise ukucwangciswa ngokuthe ngqo, i-pre-layout inokusekelwe kwi-module grab, kwibhodi ye-PCB ukuzoba uhlalutyo lokuhamba kwesignali yomgca, kwaye ngoko kusekelwe kuhlalutyo lokuhamba komqondiso, kwibhodi ye-PCB ukuzoba imodyuli yokuncedisa umgca, ukuvavanya indawo esondeleyo yemodyuli kwi-PCB kunye nobungakanani bomsebenzi. Zoba ububanzi bomgca oncedisayo we-40mil, kwaye uvavanye ingqiqo yoyilo phakathi kweemodyuli kunye neemodyuli ngokusebenzisa le misebenzi ingentla, njengoko kuboniswe kumzobo ongezantsi.

I-5, i-layout kufuneka ithathele ingqalelo itshaneli eshiya umgca wamandla, akufanele iqine kakhulu, ngokucwangcisa ukufumanisa apho amandla avela khona apho aya khona, coma umthi wamandla.

I-6, i-thermal components (njenge-electrolytic capacitors, i-crystal oscillators) i-layout kufuneka ibe kude kunikezelo lwamandla kunye nezinye izixhobo eziphezulu ze-thermal, kangangoko kunokwenzeka kwi-vent ephezulu.

I-7, ukuhlangabezana nolwahlulo lwemodyuli olubuthathaka, yonke ibhalansi yobeko lwebhodi, ugcino lwebhodi yocingo lwebhodi yonke

Iimpawu eziphezulu ze-voltage kunye ne-high-current-current zihlukaniswe ngokupheleleyo kwiimpawu ezibuthathaka zamanzi amancinci kunye ne-voltages ephantsi. Amacandelo aphezulu-voltage agxothwe kuwo onke amanqanaba ngaphandle kobhedu olongezelelweyo. Umgama we-creepage phakathi kweengxenye eziphezulu ze-voltage zihlolwe ngokuhambelana netafile eqhelekileyo

Isignali ye-analog yahlulwe kumqondiso wedijithali kunye nobubanzi bokwahlula ubuncinane obuyi-20mil, kwaye i-analog kunye neRF zicwangciswe ngendlela '-' yefonti okanye 'L' ngokweemfuno kuyilo lwemodyuli.

Isiginali yefrikhwensi ephezulu yahlulwe kwisiginali esezantsi, umgama wokwahlula ubuncinci yi-3mm, kwaye ulungelelwaniso lomnqamlezo alunakuqinisekiswa.

Ukucwangciswa kwezixhobo zeempawu eziphambili ezifana ne-crystal oscillator kunye nomqhubi wewashi kufuneka kube kude ne-interface yesekethe ye-interface, kungekhona kumda webhodi, kwaye ubuncinane be-10mm kude nomda webhodi. I-crystal kunye ne-crystal oscillator kufuneka ibekwe kufuphi ne-chip, ibekwe kwinqanaba elifanayo, musa ukugqobhoza imingxuma, kwaye ugcine indawo yomhlaba.

Isekethe yesakhiwo esifanayo ithatha "i-symmetrical" uyilo olusemgangathweni (ukusetyenziswa ngokuthe ngqo kwimodyuli efanayo) ukuhlangabezana nokuhambelana komqondiso.

Emva koyilo lwePCB, kufuneka senze uhlalutyo kunye nokuhlola ukwenza imveliso igudiswe ngakumbi.