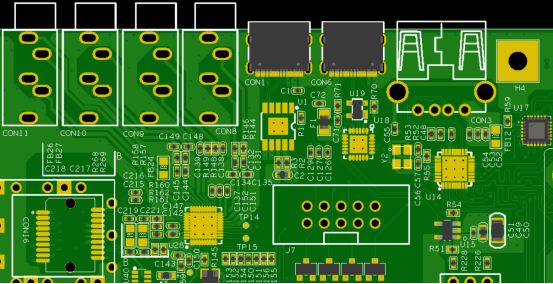

Game da shimfidar PCB da matsalar wayoyi, a yau ba za mu yi magana game da ƙididdigar ingancin siginar (SI), nazarin daidaituwar daidaitawa na lantarki (EMC), nazarin amincin ikon (PI).Magana kawai game da ƙididdigar masana'anta (DFM), ƙirar ƙira mara ma'ana kuma zai haifar da gazawar ƙirar samfur.

DFM mai nasara a cikin shimfidar PCB yana farawa tare da saita ƙa'idodin ƙira don ƙididdige mahimmancin DFM.Dokokin DFM da aka nuna a ƙasa suna nuna wasu ƙarfin ƙira na zamani waɗanda yawancin masana'antun zasu iya samu.Tabbatar cewa iyakokin da aka saita a cikin ƙa'idodin ƙira na PCB ba su keta su ba don a iya tabbatar da mafi yawan ƙayyadaddun ƙira.

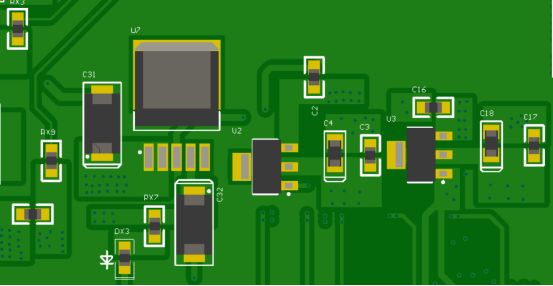

Matsalar DFM na PCB routing ya dogara da kyakkyawan tsarin PCB, kuma za a iya saita ka'idodin tafiyarwa, gami da adadin lokutan lanƙwasawa na layin, adadin ramukan gudanarwa, adadin matakai, da sauransu. Gabaɗaya, ana ɗaukar wayoyi na bincike. fita da farko don haɗa gajerun layukan da sauri, sannan kuma ana aiwatar da wayoyi na labyrinth.Ana aiwatar da inganta hanyoyin zirga-zirgar ababen hawa na duniya akan wayoyi da za a fara dage farawa, kuma ana ƙoƙarin sake yin wayoyi don haɓaka tasirin gabaɗaya da ƙirƙira DFM.

1.SMT na'urorin

Tazarar shimfidar na'urar ta cika buƙatun taro, kuma gabaɗaya ya fi 20mil don na'urorin da aka ɗora, 80mil don na'urorin IC, da 200mi don na'urorin BGA.Don haɓaka inganci da yawan amfanin ƙasa na tsarin samarwa, tazarar na'urar na iya biyan buƙatun taro.

Gabaɗaya, nisa tsakanin faifan SMD na fil ɗin na'urar yakamata ya zama sama da mil 6, kuma ƙarfin ƙirƙira gada mai siyarwar shine mil 4.Idan nisa tsakanin pads ɗin SMD bai wuce 6mil ba kuma nisa tsakanin taga mai siyar bai wuce 4mil ba, ba za a iya riƙe gadar solder ba, wanda ke haifar da manyan guntu na solder (musamman tsakanin fil) a cikin tsarin haɗin gwiwa, wanda zai jagoranci. zuwa gajeriyar kewayawa.

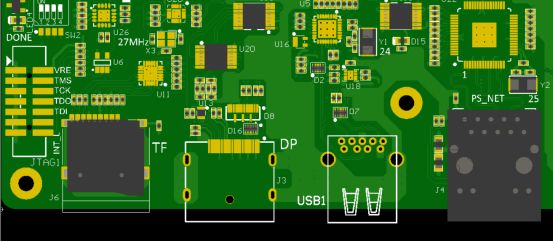

2.DIP na'urar

Ya kamata a yi la'akari da tazarar fil, jagora da tazarar na'urori a cikin tsarin siyar da igiyar ruwa.Rashin isasshen tazarar fil na na'urar zai kai ga sayar da tin, wanda zai kai ga gajeriyar kewayawa.

Yawancin masu zanen kaya suna rage amfani da na'urorin cikin layi (THTS) ko sanya su a gefe ɗaya na allon.Koyaya, na'urorin cikin layi galibi ba za a iya kaucewa ba.A cikin yanayin haɗuwa, idan na'urar in-line aka sanya a saman Layer kuma an sanya na'urar faci a kan Layer na ƙasa, a wasu lokuta, zai shafi sayar da igiyar ruwa mai gefe guda.A wannan yanayin, ana amfani da hanyoyin walda masu tsada, kamar walda mai zaɓi.

3.nisa tsakanin abubuwan da aka gyara da gefen farantin

Idan na'ura ce waldi, nisa tsakanin kayan lantarki da gefen allon shine gabaɗaya 7mm (masu sana'ar walda daban-daban suna da buƙatu daban-daban), amma kuma ana iya ƙarawa a cikin gefen tsarin samarwa na PCB, ta yadda abubuwan lantarki zasu iya zama. sanya a gefen allon PCB, idan dai ya dace da wayoyi.

Koyaya, lokacin da gefen farantin yana walda, yana iya cin karo da titin jagorar na'ura kuma ya lalata kayan aikin.Za a cire kushin na'urar a gefen farantin a cikin tsarin masana'antu.Idan kushin yana ƙarami, ingancin walda zai shafi.

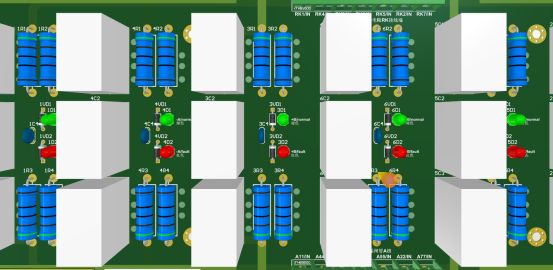

4.Distance na na'urori masu girma / ƙananan

Akwai nau'o'in kayan lantarki da yawa, nau'i daban-daban, da layukan gubar iri-iri, don haka akwai bambance-bambance a cikin hanyar haɗuwa da allunan da aka buga.Kyakkyawan shimfidar wuri ba zai iya sanya injin ya tsayayye ba, tabbacin girgiza, rage lalacewa, amma kuma yana iya samun sakamako mai kyau da kyau a cikin injin.

Dole ne a ajiye ƙananan na'urori a wani tazara a kusa da manyan na'urori.Nisan na'urar zuwa rabon tsayin na'urar ƙarami ne, akwai igiyar zafi mara daidaituwa, wanda zai iya haifar da haɗarin walda mara kyau ko gyara bayan walda.

5.Na'urar zuwa tazarar na'urar

A cikin aikin smt gaba ɗaya, wajibi ne a yi la'akari da wasu kurakurai a cikin hawan na'ura, kuma la'akari da dacewa da kulawa da dubawa na gani.Abubuwan da ke kusa da su bai kamata su kasance kusa da juna ba kuma ya kamata a bar tazara mai aminci.

Tazara tsakanin abubuwan flake, SOT, SOIC da abubuwan flake shine 1.25mm.Tazara tsakanin abubuwan flake, SOT, SOIC da abubuwan flake shine 1.25mm.2.5mm tsakanin PLCC da abubuwan flake, SOIC da QFP.4mm tsakanin PLCCS.Lokacin zayyana soket ɗin PLCC, ya kamata a kula don ba da damar girman soket ɗin PLCC (filin PLCC yana cikin kasan soket ɗin).

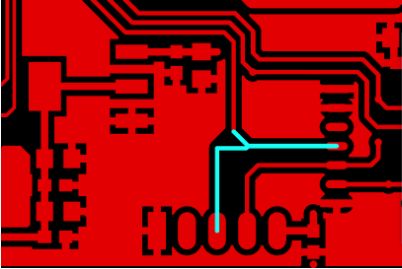

6.Line nisa / nisa layin

Ga masu zane-zane, a cikin tsari na zane, ba za mu iya la'akari da daidaito kawai da kamala na buƙatun ƙira ba, akwai babban ƙuntatawa shine tsarin samarwa.Ba shi yiwuwa ga masana'anta na hukumar don ƙirƙirar sabon layin samarwa don haihuwar samfur mai kyau.

A ƙarƙashin yanayi na al'ada, ana sarrafa nisa na layin ƙasa zuwa 4/4mil, kuma an zaɓi rami don zama 8mil (0.2mm).Ainihin, fiye da 80% na masana'antun PCB na iya samarwa, kuma farashin samarwa shine mafi ƙasƙanci.Ana iya sarrafa mafi ƙarancin faɗin layi da nisan layi zuwa 3/3mil, kuma ana iya zaɓar 6mil (0.15mm) ta cikin rami.Ainihin, fiye da 70% na PCB masana'antun na iya samar da shi, amma farashin ya ɗan fi girma fiye da na farko, bai fi girma ba.

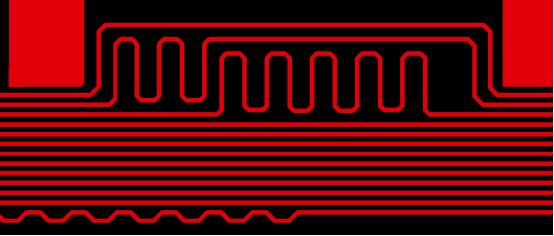

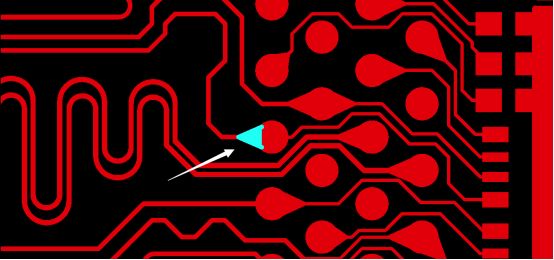

7.Kwangiya mai tsauri/kusurwar dama

An haramta zirga-zirgar Sharp Angle gabaɗaya a cikin wayoyi, ana buƙatar bugun kusurwar dama don guje wa halin da ake ciki a cikin PCB, kuma ya kusan zama ɗaya daga cikin ma'auni don auna ingancin wiring.Saboda ingancin siginar ya shafi, wayoyi na kusurwar dama za su haifar da ƙarin ƙarfin ƙarfin parasitic da inductance.

A cikin tsarin yin farantin PCB, wayoyin PCB suna haɗuwa a wani kusurwa mai mahimmanci, wanda zai haifar da matsala mai suna Angle Angle.A cikin mahaɗin etching na pcb, za a haifar da lalata da'ira mai yawa na pcb a "Acid Angle", wanda zai haifar da matsalar hutun da'ira ta pcb.Don haka, injiniyoyin PCB suna buƙatar guje wa kusurwoyi masu kaifi ko baƙon a cikin wayoyi, kuma su kula da kusurwar digiri 45 a kusurwar wiring.

8.Copper tsiri/tsibiri

Idan ya kasance babban isasshiyar tagulla na tsibirin, zai zama eriya, wanda zai iya haifar da hayaniya da sauran tsangwama a cikin jirgi (saboda jan karfensa ba a kasa ba - zai zama mai karɓar sigina).

Gilashin jan ƙarfe da tsibirai suna da yawa lebur yadudduka na tagulla mai iyo kyauta, wanda zai iya haifar da wasu matsaloli masu tsanani a cikin tudun acid.An san ƙananan wuraren tagulla suna karya PCB panel kuma suna tafiya zuwa wasu wuraren da aka tsara a kan panel, suna haifar da ɗan gajeren kewayawa.

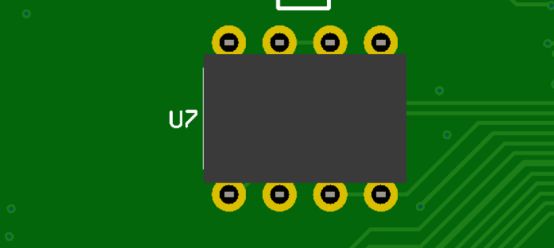

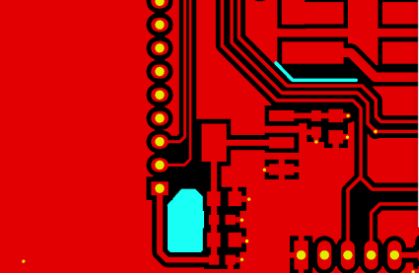

9.Rami zobe na hakowa ramukan

Zoben ramin yana nufin zoben jan ƙarfe a kusa da ramin rawar soja.Saboda juriya a cikin tsarin masana'antu, bayan hakowa, etching, da plating na jan karfe, sauran zoben jan karfe da ke kewaye da ramin rawar soja ba koyaushe yakan buga tsakiyar kushin daidai ba, wanda zai iya haifar da zoben rami ya karye.

Dole ne gefe ɗaya na zoben ramin ya fi mil 3.5, kuma zoben ramin toshe dole ne ya fi 6mil.Zoben ramin yayi kankanta sosai.A cikin aiwatar da samarwa da masana'anta, rami mai hakowa yana da juriya kuma daidaitawar layin shima yana da haƙuri.Rashin juriya na haƙuri zai haifar da zoben rami ya karya layin budewa.

10.Yaga yana zubo wa waya

Ƙara hawaye zuwa wayar PCB na iya sa haɗin haɗin da ke kan PCB ya fi dacewa, babban aminci, don haka tsarin zai kasance mafi kwanciyar hankali, don haka ya zama dole a ƙara hawaye zuwa allon kewayawa.

Ƙarin raguwar hawaye na iya guje wa yanke haɗin haɗin tsakanin waya da pad ko waya da ramin matukin jirgi lokacin da babban ƙarfin waje ya yi tasiri ga allon kewayawa.Lokacin daɗa digowar hawaye zuwa walda, zai iya kare kushin, guje wa walda da yawa don sa kushin ya faɗi, da kuma guje wa ƙaƙƙarfan etching da tsagewar da ke haifar da jujjuyawar rami yayin samarwa.