HDI: High Density interconnection o ka abbreviation, high-density interconnection, non-mechanical drilling, micro-blind hole apo i loko o ka 6 mil a emi mai, i loko a ma waho o ka interlayer uwila laina laula / laina āpau i ka 4 mil a emi mai, pad. ʻAʻole iʻoi aku ma mua o 0.35mm multilayer papa hana i kapa ʻia ʻo HDI papa.

Makapō ma: pōkole no makapō ma, ʻike i ka hoʻopili ʻana ma waena o nā papa o loko a me waho.

Kanu ʻia ma: pōkole no Buried via, ʻike i ka pilina ma waena o ka papa o loko a me ka papa o loko.

ʻO ka makapō ma ka hapa nui he puka liʻiliʻi me ke anawaena o 0.05mm ~ 0.15mm, kanu ʻia e ka laser, plasma etching a me photoluminescence, a ua hana pinepine ʻia e ka laser, i māhele ʻia i CO2 a me YAG ultraviolet laser (UV).

Mea papa HDI

1.HDI papa mea RCC, LDPE, FR4

RCC: pōkole no Resin coated copper, resin coated copper foil, RCC i haku ʻia me ka copper foil a me ka resin nona ka ili i hoʻomaʻamaʻa ʻia, wela-pale, oxidation-resistant, etc., a ua hōʻike ʻia kona ʻano ma ke kiʻi ma lalo nei: (hoʻohana ke ʻoi aku ka mānoanoa ma mua o 4mil)

Hiki i ka papa resin o RCC ke kaʻina like me FR-1/4 i hoʻopaʻa ʻia (Prepreg).Ma waho aʻe o ka hoʻokō ʻana i nā koi hana kūpono o ka papa multilayer o ke ʻano hōʻiliʻili, e like me:

(1) ʻO ka hilinaʻi insulation kiʻekiʻe a me ka hilinaʻi hole micro-conducting;

(2) Kiʻekiʻe aniani hoʻololi wela (Tg);

(3) Haʻahaʻa dielectric mau a me ka haʻahaʻa wai absorption;

(4) Hoʻopili kiʻekiʻe a me ka ikaika i ke keleawe keleawe;

(5) Kaulike mānoanoa o ka papa insulation ma hope o ka hoola ana.

I ka manawa like, no ka mea he ʻano huahana hou ʻo RCC me ka ʻole o ke aniani aniani, maikaʻi ia no ka mālama ʻana i ka lua e ka laser a me ka plasma, maikaʻi ia no ka māmā māmā a me ka lahilahi o ka papa multilayer.Eia kekahi, ʻo ka resin coated copper foil he keleawe keleawe lahilahi e like me 12pm, 18pm, a me nā mea ʻē aʻe, he mea maʻalahi ke hana.

ʻO ke kolu, he aha ka PCB mua, ka papa ʻelua?

ʻO kēia kauoha mua, ʻelua-kaupapa e pili ana i ka helu o nā lua laser, PCB core board pressure i nā manawa he nui, e pāʻani ana i nā lua laser!He mau kauoha.E like me ka mea i hōʻike ʻia ma lalo nei

1,.Ke kaomi ʻana i hoʻokahi manawa ma hope o ka ʻeli ʻana i nā lua == "ma waho o ka paʻi paʻi i hoʻokahi manawa hou i ke keleawe keleawe == "a laila nā lua drill laser.

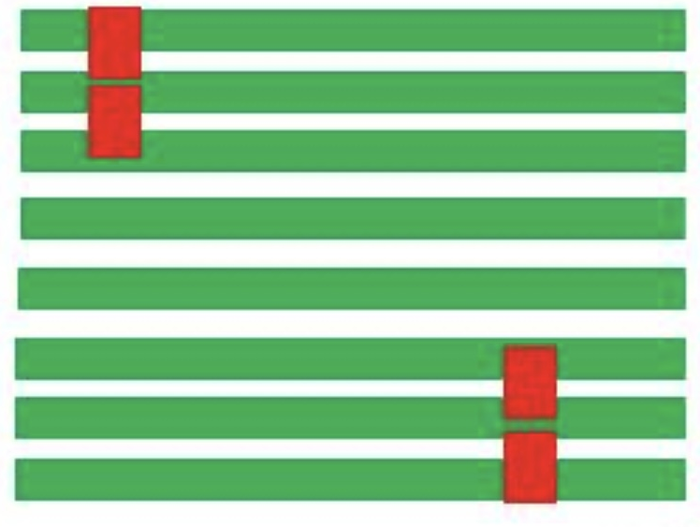

ʻO kēia ka pae mua, e like me ka mea i hōʻike ʻia ma ke kiʻi ma lalo nei

2, ma hope o ke kaomi ʻana i hoʻokahi a me ka ʻeli ʻana i nā lua == "ka waho o kekahi ʻāpana keleawe ʻē aʻe == "a laila laser, nā lua wili == "ka papa waho o kekahi ʻāpana keleawe == "a laila nā lua wili laser

ʻO kēia ke kauoha ʻelua.ʻO ka hapa nui wale nō e pili ana i ka nui o kāu laser, ʻo ia ka nui o nā ʻanuʻu.

Hoʻokaʻawale ʻia ke kauoha ʻelua i nā lua i hoʻopaʻa ʻia a me nā lua māhele.

ʻO ke kiʻi ma lalo nei he ʻewalu papa o nā puka hoʻopaʻa ʻia ʻelua, he 3-6 mau ʻāpana paʻi mua, ʻo waho o ka 2, 7 papa i kaomi ʻia, a paʻi i nā lua laser i hoʻokahi manawa.A laila kaomi ʻia nā ʻāpana 1,8 a kuʻi hou ʻia me nā lua laser.ʻO kēia ka hana ʻana i ʻelua puka laser.ʻO kēia ʻano lua no ka mea ua hoʻopaʻa ʻia, e piʻi iki ka paʻakikī o ke kaʻina hana, ʻoi aku ka nui o ke kumukūʻai.

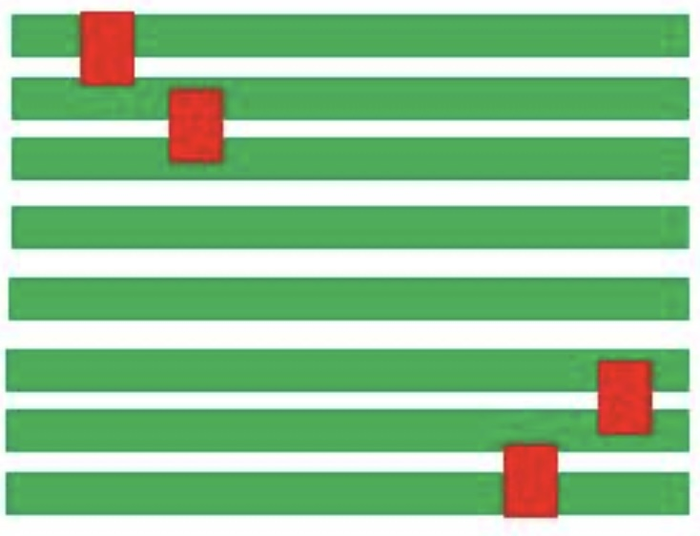

Hōʻike ka kiʻi ma lalo nei i ʻewalu mau papa o nā lua makapō keʻa o ke kauoha lua, ua like kēia ʻano hana me nā papa ʻewalu ma luna o nā lua i hoʻopaʻa ʻia, pono hoʻi e pā i nā lua laser ʻelua.Akā ʻaʻole i hui pū ʻia nā lua laser, ʻoi aku ka liʻiliʻi o ka paʻakikī.

ʻO ke kauoha ʻekolu, ʻehā kauoha a pēlā aku.