N'ezie, PCB warping na-ezokwa aka na-ehulata nke bọọdụ sekit, nke na-ezo aka na bọọdụ sekit dị larịị.Mgbe etinyere na desktọpụ, nsọtụ abụọ ma ọ bụ n'etiti osisi na-apụta ntakịrị elu.A maara ihe a dị ka PCB warping na ụlọ ọrụ.

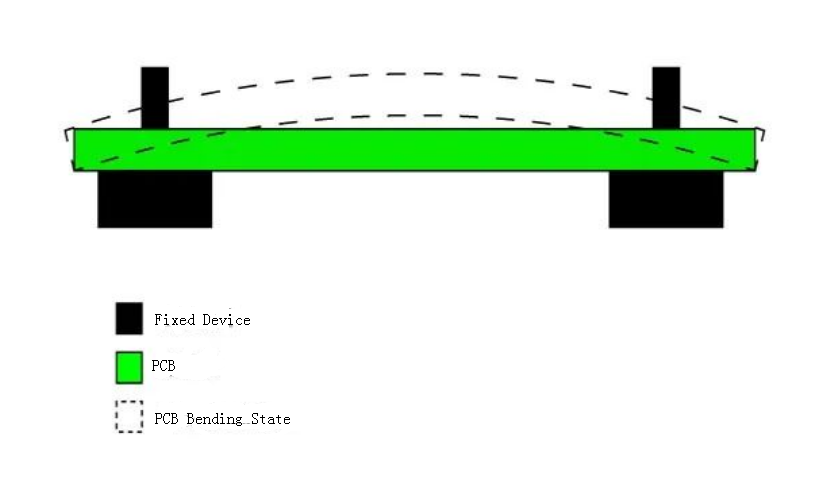

Usoro maka ịgbakọ warpage nke bọọdụ sekit bụ iji dobe bọọdụ sekit na tebụl nke nwere akụkụ anọ nke bọọdụ sekit dị n'ala wee tụọ ịdị elu nke arch n'etiti.Usoro a bụ nke a:

Warpage = ịdị elu nke arch / ogologo PCB ogologo akụkụ * 100%.

Circuit osisi warpage ụlọ ọrụ ọkọlọtọ: Dị ka IPC — 6012(1996 mbipụta) "Nkọwa maka Identification na Performance nke siri ike Bipute Boards", kacha warpage na distortion kwere maka mmepụta nke sekit mbadamba bụ n'etiti 0.75% na 1.5%.N'ihi ike usoro dị iche iche nke ụlọ ọrụ mmepụta ihe ọ bụla, e nwekwara ụfọdụ ọdịiche dị na PCB warpage akara chọrọ.N'ihi na 1.6 osisi oké ot okpukpu abụọ-akụkụ multilayer sekit mbadamba, ọtụtụ sekit osisi na-emepụta na-achịkwa PCB warpage n'etiti 0.70-0.75%, ọtụtụ SMT, BGA mbadamba, chọrọ n'ime nso nke 0.5%, ụfọdụ sekit ụlọ mmepụta ihe na ike usoro ikike nwere ike ibuli. PCB warpage ọkọlọtọ ka 0.3%.

Kedu ka esi zere warping nke bọọdụ sekit n'oge nrụpụta?

(1) The ọkara gwọrọ ndokwa n'etiti onye ọ bụla oyi akwa kwesịrị symmetrical, nkezi nke isii n'ígwé sekit mbadamba, ọkpụrụkpụ n'etiti 1-2 na 5-6 n'ígwé na ọnụ ọgụgụ nke ọkara gwọrọ iberibe kwesịrị agbanwe agbanwe;

(2) Multi-layer PCB core board na curing sheet kwesịrị iji otu ngwaahịa soplaya;

(3) The mpụta A na B akụkụ nke akara graphic ebe kwesịrị ịdị nso dị ka o kwere, mgbe A n'akụkụ bụ a nnukwu ọla kọpa elu, B n'akụkụ nanị ole na ole ahịrị, ọnọdụ a dị mfe ime mgbe etching warping.

Olee otú iji gbochie sekit warping?

1.Engineering design: interlayer semi-curing mpempe akwụkwọ ndokwa kwesịrị ekwesị;Multilayer core board na ọkara gwọchara mpempe akwụkwọ ga-esi n'otu onye na-eweta ya;Mpaghara eserese nke ụgbọ elu C/S dị n'èzí dị nso dịka o kwere mee, enwere ike iji grid nọọrọ onwe ya.

2.Drying efere tupu blanking: n'ozuzu 150 degrees 6-10 awa, ewepu mmiri vapo na efere, na-eme ka resin na-agwọta kpamkpam, wepụ nchegbu na efere;Ibé mpempe akwụkwọ tupu imeghe, ma oyi akwa dị n'ime na mkpa akụkụ abụọ!

3.Before laminates, nlebara anya kwesịrị ịkwụ ụgwọ na warp na weft ntụziaka nke siri ike efere: warp na weft shrinkage ratio abụghị otu, na anya kwesịrị ịkwụ ụgwọ ịmata ọdịiche nke warp na weft direction tupu laminating ọkara siri ike mpempe akwụkwọ;Efere isi kwesịkwara ịṅa ntị na ntụziaka nke warp na weft;Ntuziaka izugbe nke mpempe akwụkwọ ọgwụgwọ efere bụ ntụziaka meridian;Ogologo ntụziaka nke efere ọla kọpa bụ meridional;10 n'ígwé nke 4OZ ike oké ọla kọpa mpempe akwụkwọ

4.the ọkpụrụkpụ nke lamination iji kpochapụ nchekasị mgbe oyi na-atụ, trimming na raw onu;

5.Baking efere tupu mkpọpu: 150 degrees maka 4 awa;

6.It ka mma ghara ịga site n'ibu egweri ahịhịa, chemical ihicha na-atụ aro;A na-eji ihe ndozi pụrụ iche iji gbochie efere ahụ ka ọ na-ehulata na mpịachi

7.After spraying tin na ewepụghị mabul ma ọ bụ ígwè efere eke jụrụ ka ụlọ okpomọkụ ma ọ bụ ikuku sere n'elu akwa jụrụ mgbe ihicha;