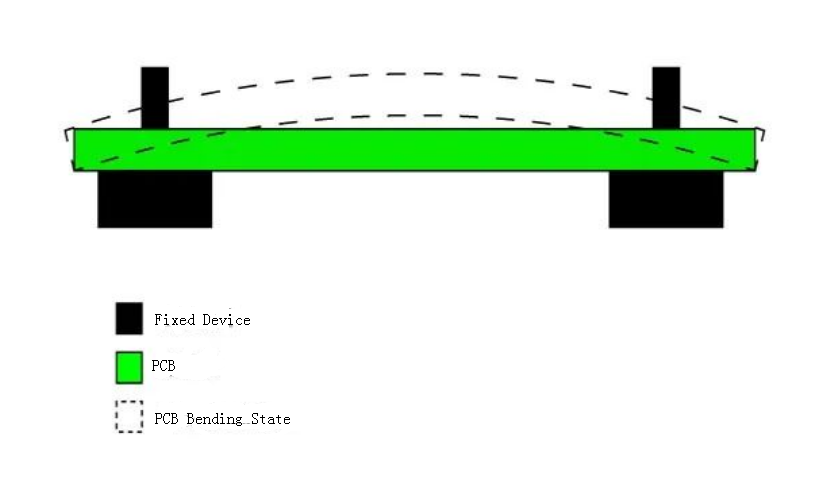

Eqinisweni, i-PCB warping iphinde ibhekisele ekugobeni kwebhodi lesifunda, okubhekiselwe ebhodini lesekethe lokuqala.Uma ibekwe kudeskithophu, iziphetho ezimbili noma phakathi kwebhodi zivela kancane phezulu.Lesi simo saziwa ngokuthi yi-PCB warping embonini.

Ifomula yokubala i-warpage yebhodi lesifunda ukubeka ibhodi lesifunda flat phezu kwetafula namakhona amane ebhodi lesifunda phansi bese ukala ukuphakama kwe-arch phakathi nendawo.Ifomula imi kanje:

I-Warpage = ukuphakama kwe-arch/ubude be-PCB side side *100%.

Izinga lemboni ye-warpage yebhodi lesifunda: Ngokuya kwe-IPC — 6012(uhlelo luka-1996) “Ukucaciswa Kokuhlonza Nokusebenza Kwamabhodi Aphrintiwe Aqinile”, ikhasi lempi eliphezulu nokuhlanekezela okuvunyelwe ukukhiqizwa kwamabhodi esekethe kuphakathi kuka-0.75% no-1.5%.Ngenxa yamakhono enqubo ahlukene efekthri ngayinye, kukhona futhi umehluko othile ezimfuneko zokulawula ikhasi lempi le-PCB.Kumabhodi ebhodi angu-1.6 awugqinsi avamile anamaceleni amaningi anezinhlangothi eziningi, abakhiqizi abaningi bebhodi lesifunda balawula i-warpage ye-PCB phakathi kuka-0.70-0.75%, amabhodi amaningi e-SMT, e-BGA, izidingo ezingaphakathi kwebanga elingu-0.5%, ezinye izimboni zebhodi lesifunda ezinomthamo wenqubo oqinile zingaphakamisa. izinga le-warpage le-PCB ukuya ku-0.3%.

Ungakugwema kanjani ukungqubuzana kwebhodi lesifunda ngesikhathi sokukhiqiza?

(1)Ukuhlelwa kwe-semi-cured phakathi kwesendlalelo ngasinye kufanele kulingane, ingxenye yezingqimba eziyisithupha zamabhodi esekethe, ukujiya phakathi kwezingqimba ezi-1-2 nezingu-5-6 kanye nenani lezingcezu eselashwe kancane kufanele lilingane;

(2)Ibhodi eliwumgogodla we-PCB enezingqimba eziningi kanye neshidi lokuphulukisa kufanele lisebenzise imikhiqizo efanayo yomphakeli;

(3)Uhlangothi olungaphandle luka-A no-B lwendawo yesithombe somugqa kufanele lusondele ngangokunokwenzeka, lapho uhlangothi luka-A luyindawo enkulu yethusi, uhlangothi luka-B lube yimigqa embalwa kuphela, lesi simo kulula ukwenzeka ngemva kokuhlabana.

Indlela yokuvimbela i-warping board board?

1.Idizayini yobunjiniyela: ukuhlelwa kweshidi le-interlayer semi-curing kufanele kufanele;Ibhodi eliwumgogodla we-multilayer kanye neshidi eliphulukisiwe kuzokwenziwa kumhlinzeki ofanayo;Indawo eyingcaca yendiza ye-C/S yangaphandle iseduze ngangokunokwenzeka, futhi igridi ezimele ingasetshenziswa.

2.I-Drying plate ngaphambi kokuvala: ngokuvamile ama-degree angu-150 amahora angu-6-10, ungafaki umhwamuko wamanzi epuletini, futhi wenze i-resin iphulukise ngokuphelele, isuse ukucindezeleka epuletini;Ishidi lokubhaka ngaphambi kokuvula, kokubili ungqimba lwangaphakathi nohlangothi olukabili ludinga!

I-3.Ngaphambi kwama-laminates, kufanele kuqashelwe isiqondiso se-warp ne-weft yepuleti eliqinile: isilinganiso se-warp ne-weft shrinkage akufani, futhi kufanele kukhokhwe ukunakwa ukuhlukanisa isiqondiso se-warp ne-weft ngaphambi kwe-laminating semi-solidified sheet;I-core plate kufanele futhi inake isiqondiso se-warp ne-weft;Isiqondiso esijwayelekile seshidi lokuphulukisa ipuleti yisiqondiso se-meridian;Isiqondiso eside se-copper clad plate siyi-meridional;Izendlalelo ezingu-10 zeshidi lethusi elingu-4OZ lamandla

4.ubukhulu be-lamination ukuze kuqedwe ukucindezeleka ngemva kokucindezela okubandayo, ukusika unqenqema oluluhlaza;

I-5.Ipuleti yokubhaka ngaphambi kokubhoboza: ama-degree angu-150 amahora angu-4;

I-6.Kungcono ukungahambi ngebhulashi lokugaya ngomshini, ukuhlanza amakhemikhali kunconywa;Ukulungiswa okukhethekile kusetshenziselwa ukuvimbela ipuleti ukuthi lingagobi futhi ligoqe

7.Ngemva kokufafaza ithini phezu kwemabula eyisicaba noma ipuleti lensimbi ukupholisa okungokwemvelo ekamelweni lokushisa noma ukupholisa umbhede ontantayo ngemva kokuhlanza;