Kazhinji: kana ichienzaniswa neyakagadzirwa maitiro e-multi-layer board uye kaviri-layer board, pane 2 mamwe maitiro, zvichiteerana: mutsara wemukati uye lamination.

Muchidimbu: mukugadzirwa kweplate-layer plate, mushure mokunge kucheka kwapera, kuchera kuchaitwa, uye ipapo mumhangura, mutsara;Mukugadzira maitiro e-multi-layer board, mushure mekuvhurwa kwechinhu chapera, hachizocherwa zvakananga, asi chokutanga chinoda kupfuura nemutsetse wemukati uye lamination, uyezve kupinda mumusangano wekuchera kudhiraivha, uyezve. mumhangura uye mutsetse.

Ndiko kuti, pakati pekuvhura uye maburi ekuchera, maitiro maviri e "mukati mutsara" uye "lamination" anowedzerwa.Iwo ari pamusoro ndiwo mutsauko pakati peakawanda-layer board uye kaviri-layer board kugadzirwa.

Tevere, ngatitarisei kuti maitiro maviri emutsetse wemukati uye lamination ari kuitei

Mutsara wemukati

Iyo "mutsara" maitiro mukugadzirwa kwemahwendefa maviri-layer, kusanganisira firimu compression, exposure, development (kana iwe ukakanganwa, unogona kudzokera shure uye unotarisa).

Iyo "yemukati wedunhu" pano haisi nyore!Kuwedzera kune yemukati laminated firimu, kuratidzwa kwemukati, kukura kwemukati, inosanganisirawo mukati mekutanga kurapwa, mukati mukati, kubviswa kwemafirimu mukati uye mukati meAOI.

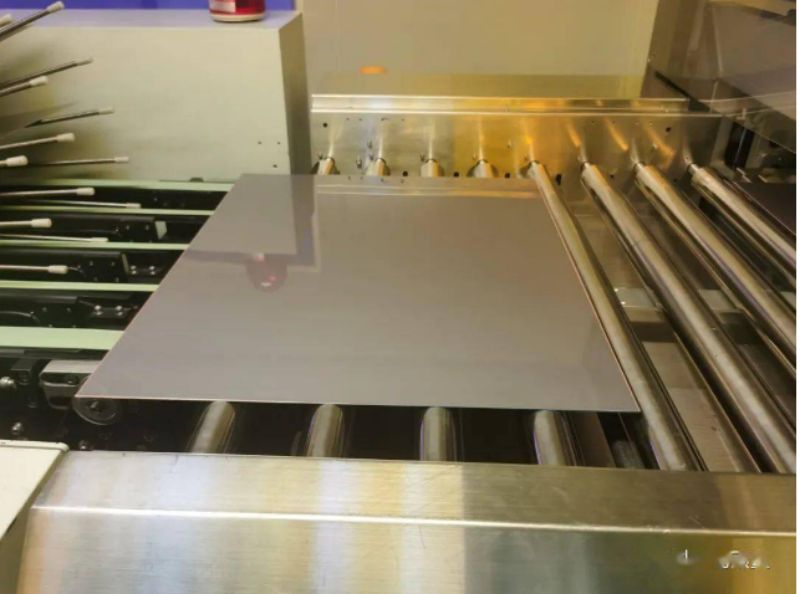

Muchirongwa chekugadzirwa kweplate-layer-layer, bhodhi mushure mekunge kugadzika kwemhangura kwapera, pasina mutsara wekugadzira, zvakananga mufirimu inotsikirira, saka hapana chikonzero chekuita mamwe pre-pressing treatment.Uye iyo copper foil plate pano, ichangobva kubva kumusangano wekucheka, pamusoro pebhodhi pachava nekusachena, saka

Pamberi peiyo yemukati laminate firimu, zvinofanirwa kufambisira mberi kurapwa uye kuchenesa, kushandiswa kwemakemikari kuita, kutanga kubvisa mafuta, mvura, mvura yakachena, maviri micro-etching (bvisa pamusoro pemarara), uye ipapo mvura, uye ipapo pickling (mushure mezvo. kushambidza, iyo nzvimbo inenge iine oxidized, saka inoda pickling), ipapo mvura, wozooma, uye zvakare mufirimu yemukati laminate.

Inner laminate film isati yarapwa

Mushure mekudzvanya bhodhi, nekuti harina kucherwa, rinotaridzika rakadzikama.

Kudzvanya firimu, kuratidzwa, kusimudzira, izvo chaizvo nyaya dzezvibatanidza izvi, zvakaunzwa muchinyorwa chekugadzirwa kweplate-layer-layer, pano hazvidzokororwe.

Mushure mokunge kugadzirwa kwapera, chikamu chendarira chichaonekwa, nokuti kunze kwekunze inzira yakanaka yefirimu, mukati memukati inzira yakaipa yefirimu.Naizvozvo, mushure mekugadzirwa kwekunze kwedenga kwapera, iyo yakafumurwa yemhangura ndiyo chikamu chinoda kuchengetwa, uye mhangura yakafumurwa mushure mekugadzirwa kwemukati kwemukati ndicho chikamu chinoda kudzimwa, saka.

Iyo yemukati etching process uye yekunze etching process inosiyanawo, iyo yemukati etching ndeye alkaline process, panguva yekucheka, iyo yakaoma firimu ichiri mukati, chikamu chisina yakaoma firimu (yakafumurwa mhangura) inotemwa kutanga, uye ipapo mold inobviswa.

Iyo etching yedenga rekunze inotanga yabviswa yozoiswa, uye mutsara wacho unodzivirirwa zvishoma nematani emvura.

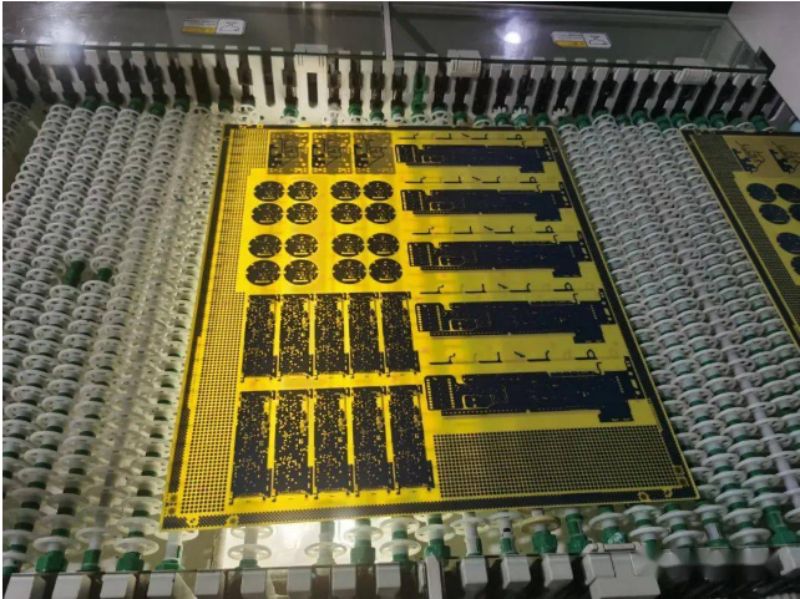

Yemukati firimu etching mutsara, kuruboshwe ndiko kukonzeresa etching, kurudyi ndiko kukonzeresa kubviswa kwefirimu.

Mushure mekuvhara bhodhi redunhu, mhangura yakawandisa yakave yakadzikwa, uye chikamu chakasara chefirimu yakaoma haina kubviswa.

Bhodhi redunhu mushure mekubvisa.

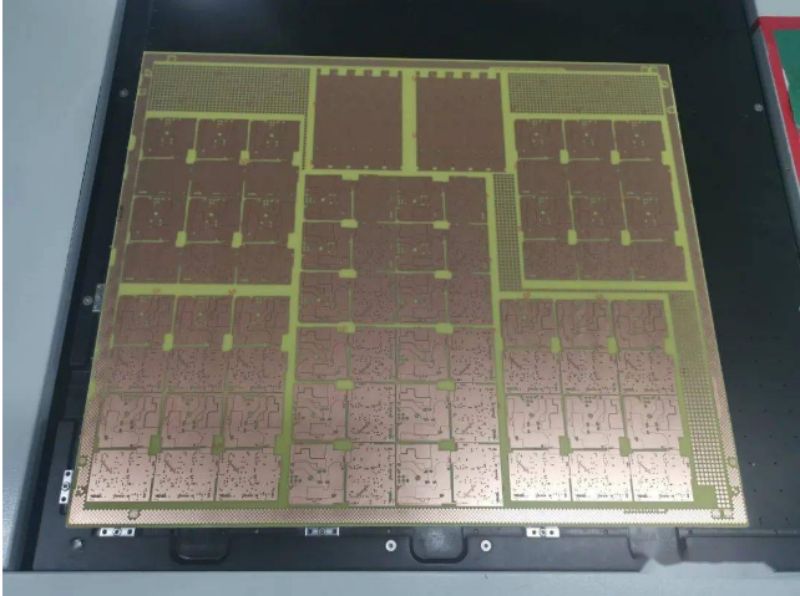

Mushure mokunge mutsara wemukati wefirimu wapera, mukati memutsara wemutsara wakaitwa zvachose, panguva ino, uye ipapo AOI optical discovery, kuona kuti hapana dambudziko, unogona kuita lamination process.

Lamination:

Ichangobva kugadzirwa bhodhi, tinoridaidza kuti mukati memukati bhodhi, kana iri 4 akaturikidzana ebhodhi, pachave ne1 mukati memukati bhodhi, kana iri 6 akaturikidzana ebhodhi, pachave ne2 mukati mabhodhi emukati.

Chinangwa chikuru chegadziriro iyi ndechekuita kuti mukati mepakati pendiro uye yekunze layer ibatanidzwe pamwechete kuti iite yakazara.Inotarisira iyo yekubatanidza zvinhu, inonzi PP, Chinese inonzi semi-curing sheet, iyo huru kuumbwa iresin uye girazi fiber, inozoridzawo yemukati yepakati bhodhi uye yekunze yemhangura foil insulation chinangwa.

Kuti uve nechokwadi chemhando yeakawanda-layer board, mutengesi wePP weJialichuang achiri South Asia Electronics.

Kazhinji, iyo lamination process yakakamurwa kuita matanho mana muhurongwa: Browning, pre-stacking, platen, uye kudzvanya.Tevere, ngatitarisei zvakadzama zvega rega rega rega.Iyo yemukati core ndiro mushure mekunge kubviswa kwefirimu kwapera kunoiswa browned kutanga.The browned circuit board ichawedzera chidimbu chefirimu yakasvibiswa pamusoro pebhodhi redunhu, iyo iine brown metallized substance, uye nzvimbo yayo haina kuenzana, kuitira kuti zvive nyore kubatana nePP.

Nheyo yacho yakafanana nekugadzirisa vhiri rebhasikoro, nzvimbo yakaputsika inofanira kuiswa kunze nefaira yekuvandudza glue adhesion.

Iyo Browning maitiro zvakare ikemikari reaction process, iyo inoenda kuburikidza ne pickling, alkali washing, multi-channel washing, kuomesa, kutonhora uye mamwe maitiro.

prelap

Iyo pre-stacking process, inoitwa mumusangano-isina guruva, ichaisa iyo yepakati ndiro uye PP pamwechete.A PP inoiswa kune rumwe rutivi rwepakati ndiro.Hurefu nehupamhi hwePP huchave 2mm hombe pane yepakati ndiro kudzivirira maburi edge mushure mekudzvanya.

Raft:

Chinangwa chikuru chemutsara weplate ndechekuwedzera chidimbu chemhangura yemhangura pamusoro pePP layer kugadzirira mutsara unotevera wekunze.Mukuwedzera, ndiro yesimbi uye kraft paper ichawedzerwa kune yekunze layer.lamination

Matanho mashoma ekutanga ndeekugadzirira yekupedzisira lamination.

Usati waita laminating, kuitira kudzivirira warping, pachava nechivharo ndiro, anenge 12mm gobvu, simbi.

Laminating inosanganisira nzira mbiri dzekutsikirira uye kutonhora kudzvanya, zvichiteerana mushizha rinopisa uye rinotonhora.Ichi chinongedzo chakakosha, kufunga nezvezvinhu zvinosanganisira vacuum, tembiricha, kudzvanywa, nguva, zvinhu izvi zvinoshanda pamwe chete, kuitira kugadzira emhando yepamusoro mabhodhi edunhu.

Somuenzaniso, mune imwe nhambo yenguva, kuti tembiricha yakadini, kuti kumanikidzika kwakadini, uye urefu hwenguva inodiwa, zvinofanira kunyatsogadziridzwa.

Mushure mekupera kwekuita uku, PP uye yemukati core plate uye yekunze yemhangura foil ichave yakanyatsobatanidzwa pamwe chete.

Mushure mokubuda mukudhinda, kubviswa kwe otomatiki kunoitwa, ndiro yesimbi inobviswa, uye inotumirwa kukamuri yeplatoon zvakare mushure mekugaya.Sezvinoratidzwa mumufananidzo 11, muchina uri kubvisa ndiro yesimbi.

Iyo laminated multi-layer redunhu bhodhi ichadzoserwa kune yayo yekutanga yekuchera workshop kuti iboore, uye iyo yese yemaitiro yakafanana neyekugadzira nzira yekaviri-layer board.