Kwi-welding yebhodi yeesekethe ezimbini, kulula ukuba nengxaki yokubambelela okanye i-welding virtual. Kwaye ngenxa yokwanda amacandelo amabini-umaleko ibhodi yesekethe, uhlobo ngalunye amacandelo kwiimfuno ukuwelda iqondo lobushushu ukuwelda kunye nokunye azifani, nto leyo ekhokelela ekwandeni kobunzima ukuwelda ibhodi yesekethe ezimbini-umaleko, kubandakanywa ukuwelda umyalelo welding kwezinye iimveliso zineemfuno ezingqongqo.

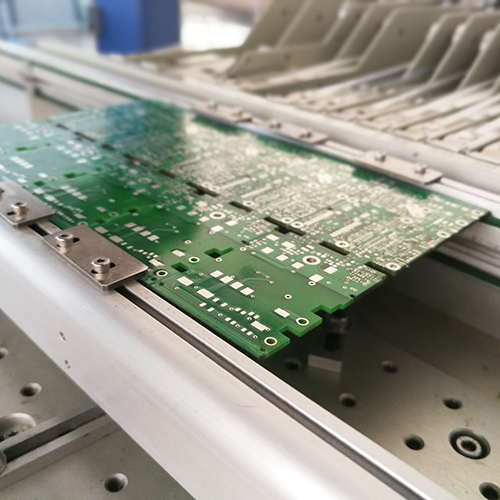

Inkqubo ye-welding yebhodi yesekethe enamacala amabini:

Lungiselela izixhobo kunye nezixhobo, kubandakanywa iibhodi zesekethe, amacandelo, i-solder, i-solder paste, kunye ne-solder iron.

Coca umphezulu webhodi kunye nezikhonkwane zecandelo: Coca umphezulu webhodi kunye nezikhonkwane zecandelo kunye ne-detergent okanye utywala ukuqinisekisa umgangatho we-welding kunye nokuthembeka.

Amacandelo eendawo: Beka amacandelo kwibhodi yesekethe ngokweemfuno zoyilo lwebhodi yesekethe, ubeke ingqalelo kwisalathiso kunye nokuma kwamacandelo.

Faka i-solder paste: Faka i-solder pad kwi-pad kwizikhonkwane zecandelo kunye nebhodi yesekethe ukulungiselela i-welding.

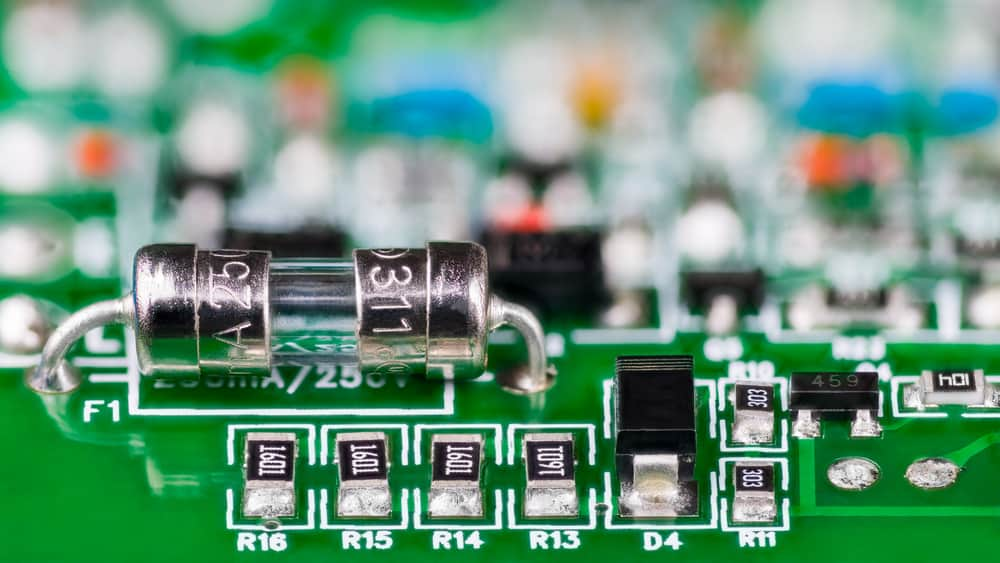

Amacandelo e-Welding: Sebenzisa i-iron soldering yombane kwi-weld components, qaphela ukugcina ubushushu obuzinzileyo kunye nexesha, ukuphepha ukufudumeza okugqithisileyo okanye ixesha le-welding lide kakhulu.

Jonga umgangatho we-welding: khangela ukuba i-welding point iqinile kwaye igcwele, kwaye akukho nto i-welding, i-welding evuzayo kunye nezinye izinto.

Ukulungisa okanye ukubuyisela kwakhona: Kumanqaku e-welding aneziphene ze-welding, ukulungiswa okanye ukulungiswa kwakhona kuyafuneka ukuze kuqinisekiswe umgangatho we-welding kunye nokuthembeka.

Ingcebiso ye-welding yebhodi yesekethe 1:

Inkqubo ye-welding ekhethiweyo ibandakanya: ukutshiza nge-flux, ukutshisa ibhodi yesekethe, i-welding dip kunye ne-drag welding. Inkqubo yokugubungela i-Flux Inkqubo yokugqoka i-flux idlala indima ebalulekileyo kwi-welding ekhethiweyo.

Ekupheleni kokufudumala kwe-welding kunye ne-welding, i-flux kufuneka isebenze ngokwaneleyo ukukhusela ukuveliswa kweeBridges kunye nokukhusela i-oxidation yebhodi yesiphaluka. Ukutshiza nge-Flux Ibhodi ithwalwa yi-X / Y manipulator phezu kwe-nozzle ye-flux, kwaye i-flux ifafazwe kwi-pcb board welding position.

Ingcebiso yesi-2 yebhodi yesekethe:

Kwincopho ye-microwave ekhethiweyo yokuwelda emva kwenkqubo yokuphinda ifakwe kwi-solder, kubalulekile ukuba i-flux itshizwe ngokuchanekileyo kwaye uhlobo lwe-microporous spray aluyi kungcolisa indawo engaphandle kwe-solder joint.

Ububanzi bendawo ye-micro-spot yokutshiza i-flux inkulu kune-2mm, ngoko ke ukuchaneka kwendawo ye-flux efakwe kwibhodi yesekethe yi-± 0.5mm, ukwenzela ukuba kuqinisekiswe ukuba i-flux ihlala igutyungelwe kwi-welding part.

Ingcebiso yesi-3 yebhodi yesekethe:

Iimpawu zenkqubo ye-welding ekhethiweyo inokuqondwa ngokuthelekisa kunye ne-soldering wave, umahluko ocacileyo phakathi kwezi zibini kukuba inxalenye ephantsi yebhodi yesekethe kwi-welding wave ifakwe ngokupheleleyo kwi-solder yolwelo, ngelixa i-welding ekhethiweyo, kuphela iindawo ezithile ezithile zidibene ne-solder wave.

Ekubeni ibhodi yesekethe ngokwayo iphakathi ubushushu ombi, ayiyi kufudumala kwaye inyibilike amalungu e-solder kwindawo esecaleni kwamacandelo kunye nebhodi yesekethe xa i-welding.

I-flux kufuneka ifakwe ngaphambili phambi kwe-welding, kwaye xa kuthelekiswa ne-soldering ye-wave, i-flux ifakwe kuphela kwindawo engezantsi yebhodi ukuze idityaniswe, kunokuba ibhodi ye-pcb yonke.

Ukongezelela, i-welding ekhethiweyo isebenza kuphela kwi-welding ye-plug-in components, i-welding ekhethiweyo yindlela entsha, kunye nokuqonda ngokucokisekileyo inkqubo ekhethiweyo ye-welding kunye nezixhobo eziyimfuneko ukuze kuphumelele i-welding.

I-welding yebhodi yesekethe yamacala amabini kufuneka iqhutywe ngokuhambelana namanyathelo okusebenza achaziweyo, ingqalelo kukhuseleko kunye nokulawula umgangatho, kwaye uqinisekise umgangatho we-welding kunye nokuthembeka.

Ukuwelda ibhodi yesekethe emacaleni kabini kufuneka kuthathelwe ingqalelo le miba ilandelayo:

Ngaphambi kwe-welding, coca umgangatho webhodi yesekethe kunye nezikhonkwane zecandelo ukuqinisekisa umgangatho we-welding kunye nokuthembeka.

Ngokweemfuno zoyilo lwebhodi yesekethe, khetha izixhobo ezifanelekileyo ze-welding kunye nezixhobo, ezifana ne-solder, i-solder paste, njl.

Ngaphambi kwe-welding, thatha imilinganiselo ye-ESD, efana nokunxiba amakhonkco e-ESD, ukukhusela umonakalo we-electrostatic kumalungu.

Gcina ubushushu obuzinzileyo kunye nexesha ngexesha lenkqubo ye-welding ukuphepha ukufudumeza okugqithisileyo okanye ixesha elide lokutshisa, ukuze ungonakalisi ibhodi yesiphaluka okanye amacandelo.

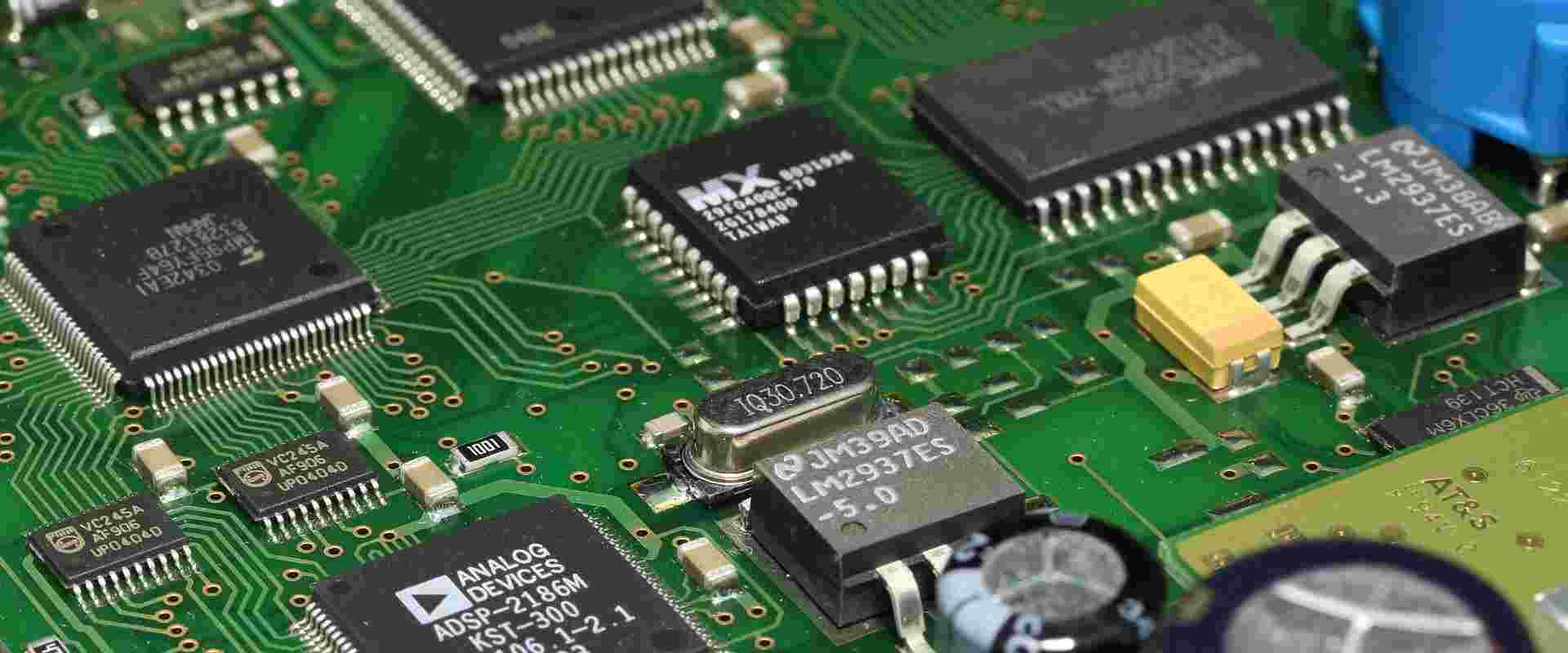

Inkqubo ye-welding iqhutyelwa ngokubanzi ngokuhambelana nomyalelo wezixhobo ukusuka kwi-low ukuya phezulu kwaye ukusuka kwincinci ukuya enkulu. Eyona nto iphambili inikwe ukuwelda iitshiphusi zesekethe ezidityanisiweyo.

Emva kokuba i-welding igqityiwe, jonga umgangatho we-welding kunye nokuthembeka. Ukuba kukho naziphi na iziphene, lungisa okanye weld kwakhona ngexesha.

Kwi-welding ye-welding ye-welding, i-welding yebhodi yeesekethe eziphindwe kabini kufuneka ihambelane ngokungqongqo kunye neenkcukacha zenkqubo efanelekileyo kunye neemfuno zokusebenza ukuze kuqinisekiswe umgangatho kunye nokuthembeka kwe-welding, ngelixa uhlawula ingqalelo ekusebenzeni okukhuselekileyo ukuphepha ukulimaza ngokwayo kunye nokusingqongileyo.